Unique for its strength, lightness of weight and corrosion resistance

Excellent strength to weight ratio

Excellent strength to weight ratio- Practically inert to chloride, chlorines and seawater

- Mechanical Properties: tensile, yield & elongation charts

- Titanium Grade 2, 5, 7 and 23 chemistry & specifications

- Datasheets for Grade 2 and Grade 5

- Titanium fastener styles

- Titanium FAQ of the Week

- Fastener stock & availability

Titanium fasteners are best known for being strong, lightweight, and corrosion resistant. They are critical to many industries including chlor alkali, marine, off-shore oil & gas, desalination, medical, and pulp and paper. Grade 2 and 5 are the most commonly used grades of titanium screws:

• Grade 2 (UNS R50400 / 3.7035) :Commercially pure titanium and the most common grade for screws.

• Grade 5 (UNS R56400 / 3.7165): Superior strength-to-weight ratio for a unique combination of corrosion and high strength.

Corrosion Resistance

Saltwater

Perhaps the most notable attribute of titanium fasteners are their superior corrosion resistance to salt water / seawater. Titanium screws have the unique ability to rapidly regrow their protective passive layer in the presence of oxygen, giving them unparalleled resistance to salt water environments.

• Proven resistance in decades of polluted seawater

• Usable in ocean depths of a mile beneath the surface

• Resistant to high velocity, rapidly moving currents as well as stagnant seawater

• Not affected by the presence of sulfides in seawater

• Ideal for sea splash and tide zones

• Seawater resistant to temperatures as high as 500°F (260°C)

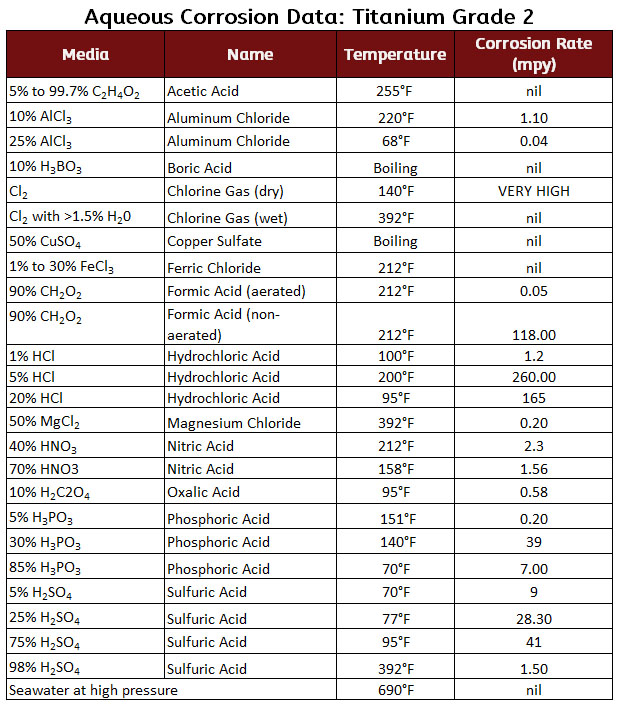

Chloride, Chlorine & Other Media

Similar to salt water, titanium’s strong, protective oxide film which regenerates in oxygen makes it extremely resistant to oxidizing environments, and chlorides solutions, including hypochlorites, chlorates, perchlorates, sodium chlorite, and chlorine dioxide. This protection holds true as long as moisture is present – which can be as little as 50ppm of moisture. Oxidizing environments in the absence of water can cause titanium to rapidly corrode or even ignite. Titanium screws are not resistant to reducing media and acids (see chart).

Lightweight Strength

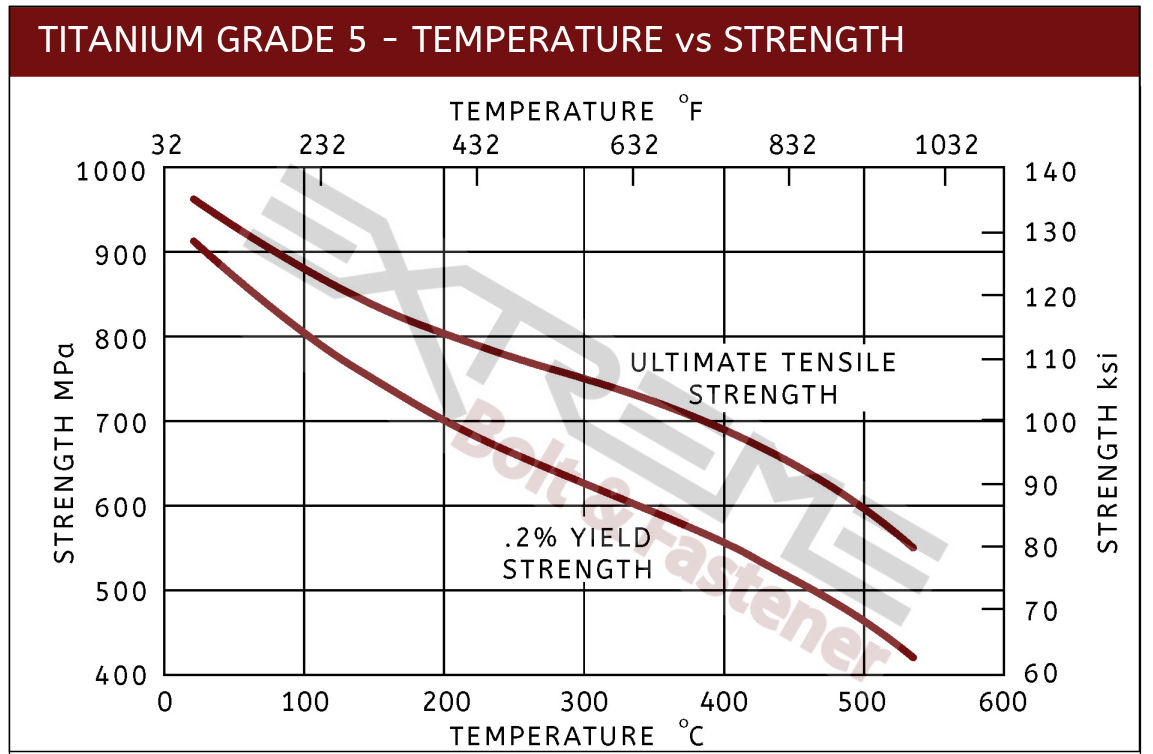

Not only are titanium grade 5 fasteners extremely strong, offering 148 ksi UTS and 138ksi yield they are also incredibly light. With a density of 4.51 g /cm3, titanium has on of the the highest strength-to-weight ratios available to industry. Titanium Grade 5 screws are 4 times stronger than 316 stainless steel at nearly half the weight. This makes titanium fasteners ideal for applications that require both lightness of weight and excellent strength such medical, military and sporting goods.

Which Grade is Best for Your Application?

The most common grades of of Titanium fasteners are Grade 2 (commercially pure Ti) and Grade 5 (Ti 6Al-4V - high strength). Still not sure? With decades of materials expertise and industrial experience, our engineers can help you select the best titanium fastener for your application. Other resources include: Titanium Torque Specs.

Titanium Fastener Stock and Availability

Stock

Titanium screws, bolts, nuts, washers, lock washers, hose clamps and threaded rods are stocked and ready to ship. Below is a list of some of the most commonly stocked sizes but please check with us as other sizes are available and our stock is updated regularly.

• Grade 2: Sizes M2 - M8; #2 - 3/8”

• Grade 5: Sizes M2 – M16; #4 – ½”

Custom Availability

Titanium screw styles, if not in stock, can be made to order with minimum quantities, typically around 25 pcs. We also can provide fasteners in Titanium grade 7 and grade 23. The normal lead time for standard titanium is only few days. For custom titanium fasteners, we can typically ship in about 4 weeks. Be sure to contact us for specific lead times and expediting needs.

• Diameter sizes: Standard #00 – 4” in diameter / Metric M1.2 – M48

• Threads: UNC, UNF, UNJ, UNR, Rolled or Cut

• Minimum Volume – Typically 25pcs depending on size and stock

• Custom to print

• All ANSI/ASME and DIN / ISO standards

• NACE MR0175, ASTM, ASME, MIL specifications, DFAR and Domestic available

Expediting Options

Time critical? Just let us know! We have a large stock of grade 2 and 5 titanium fasteners, ready to ship and do our best to accommodate your needs.

Titanium Fastener Styles

| Titanium Screws | 12 Point Screws, Button Head Cap Screws, Flat Head Screws, Hex Head Cap Screws, Pan Head Screws, Security Screws, Set Screws, Socket Head Cap Screws, Vented Screws |

| ||

| Titanium Bolts | Hex Head Bolts, Shoulder Bolts, Wedge Anchor Bolts | • DIN 931 • DIN 933 • ISO 4014 • ISO 4017 • ISO 7370 | ||

| Titanium Nuts | Hex Nuts, Lock Nuts | • DIN 439 / ISO 4035 • DIN 934 / ISO 4032 • DIN 985 / ISO 7040 • DIN 986 • DIN 980 / ISO 7042 / ISO 19513 • DIN 6923 / ISO 4161 | ||

| Titanium Studs/Rod | Studs, Threaded Rod, Weld Studs | • DIN 975 • DIN 976 | ||

| Titanium Washers | Flat Washers, Lock Washer | • DIN 125 / ISO 7089 / ISO 7090 • DIN 126 / ISO 7091 • DIN 127 / ISO 7090 • DIN 9021 / ISO 7093 | ||

| Titanium Hose Clamps | Medium Duty Hose Clamps, Worm Drive Hose Clamps |

|

Titanium Grades, Chemistry & Specifications

Titanium Grade 2 / UNS R50400 / 3.7035 (Commercially Pure)

Unalloyed titanium; Commercially pure titanium is the most common grade of titanium utilized throughout industry due to its ease of availability and good properties. Learn more about titanium grade 2.

Titanium Grade 2 Specifications: UNS R50400, ASTM B 348, AMS 4921, ASTM F 67, ISO 5832-2, EN 3.7035, ASTM F467 (Nuts), ASTM F468 (Bolts, Screws, Studs)

Titanium Grade 5 (Ti 6Al-4V) / UNS R56400 / 3.7165

Known as the “workhorse” of the titanium alloys, Ti 6Al-4V, or Grade 5 titanium, is 2x stronger than titanium grade 2. This alloy offers high strength and light weight, useful formability and high corrosion resistance. Ti 6AI-4V finds many uses in the aerospace, medical, marine and chemical processing industries. Learn more about grade 5 titanium.

Titanium Grade 5 Specifications: UNS R56400, EN 3.7165, ASTM - B265, B348, B381, B861, F467 and F468, AMS - 4911, 4928, 4935, 4965 and 4967, MIL-T - 9046 and - 9047, EN 3.7165, ASTM F467 (Nuts), ASTM F468 (Bolts, Screws, Studs)

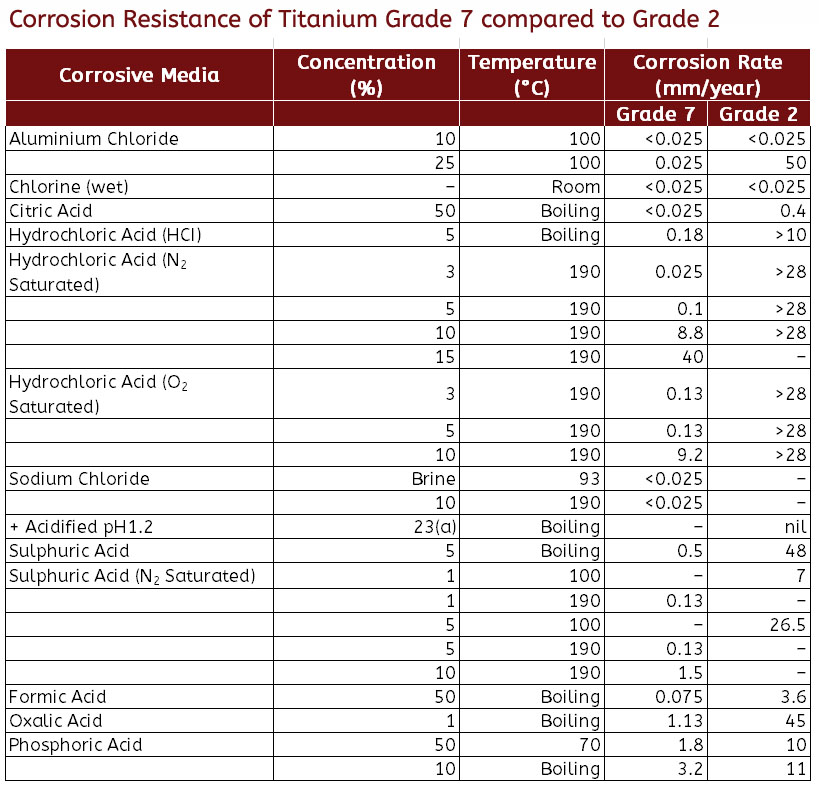

Titanium Grade 7 (Ti-0.15Pd) / UNS R52400 / 3.7235

Grade 7 is the most corrosion resistant of all titanium alloys and is typically used in chemical processes and production equipment components. Similar to Grade 2, but with the addition of 0.12 to 0.25% palladium, Grade 7 has enhanced corrosion resistance to reducing acids and localized attack in hot halides. Click here to see a chart that compares titanium grade 7 to grade 2.

Titanium Grade 7 Specifications: ASTM - B265, B337, B338, B348, B363, B381, B861 and B862, EN 3.7235, ASTM F467 (Nuts), ASTM F468 (Bolts, Screws, Studs)

Titanium Grade 23 (TI 6AL-4V ELI) / UNSR56401 / 3.7165

Titanium grade 23 or TI 6AL-4V ELI is an Extra Low Intersticial grade. This grade is similar to Grade 5, but because of the low intersticials, its mechanical properties are enhanced. This ELI grade is often found in more demanding medical device applications as well as industrial applications.

Titanium Grade 23 Specifications: UNS R52400, ASTM - B265, B348, B363, B381, B861, B862 andF136, AMS - 4907, 4930 and 4956, EN 3.7165, ASTM F467 (Nuts), ASTM F468 (Bolts, Screws, Studs)

Other titanium grades are also available upon request.

Titanium Frequently Asked Question of the Week

| High Strength Titanium Grade 5 Compared to Monel K500 |

Q: How does Monel K500 Compared to Titanium Grade 5? A: Both Monel and titanium will both offer excellent resistance to saltwater conditions. Titanium will perform slightly better than Monel in stagnant seawater – but this is minuscule. The main differences are strength and applications. In terms of strength, Monel K500 will offer about 160ksi of tensile strength compared to grade 5 titanium bolts 148ksi. – slightly higher. Monel K500 bolts are also more commonly used by the military for saltwater conditions and can be quoted per MIL Spec. In comparison, titanium grade 5 per spec TI 6AL-4V can be used in medical applications for inertness, biocompatibility and strength. |

Mechanical Properties

Titanium's Resistance to Chlorine

Corrosion Data

Titanium Grade 5 Temperauture vs Strength

Titanium Screws

| Titanium 12 point screws are best for applications that require higher torque than a socket head cap screw or head head bolt, however they are be less economical due to the complexity to manufacture the head. Available in 1/4" or larger sizes. | • IFI-115 • MIL SPEC • DIN 34822 • DIN 34821 | |

| Titanium button head screws offer a wide clamping area and low profile. Button heads are most commmonly available with a socket driver and are best for fastening material that is too thin to counter bore. | • ASME B18.3 • ASME 18.3.4M • DIN 7380 / ISO 7380 | |

| | Titanium flat head screws are typically offererd in a 82° countersink angle, but can be custom made to other angles from 60° -120°. Available in slotted and socket drivers, titanium flat head screws are designed to be flush with the surface. Phillips, 6-lobe, torx and tamperproof drivers can also be specially manufacturing per drawing. | • ASME B18.3 • ASME B18.3.6 • DIN 963 / ISO 2009 • DIN 965 / ISO 7046 • DIN 7991 / ISO 10642 |

| Hex head cap screws offer an added washer face to the bolt head which is lacking on a hex bolt. Titanium hex head cap screws provide tighter dimensional tolerances over hex bolts. These screws are best used for applications that need a high clamping force with easy access. Generally available in #2 - 1/2" sizes and metric sizes. | • ASME B18.6.3 • DIN 931 / ISO 4014 • DIN 933 / ISO 4017 • DIN 961 / ISO 8676 | |

| Titanium pan head screws feature a rounded top are with either a slotted or phillips driver. These screws are best used for small diameter fastener needs, as well as low torque applications. | • ASME B18.6.3 • DIN 7985 • DIN 921 • DIN 85 / ISO 1580 • DIN 84 / ISO 1207 (cheese head) • DIN 966 / ISO 7047 (raised counter sunk) | |

Security Screws Security Screws | When security is critcal, titanium tamper proof driver designs provide resistance to unwanted removal due to the fact that they are not accessible with an ordinary driver. Titanium security screws are available in several different drive styles and heads, as well as custom per print. | |

| Titanium set screws are available in cup, cone, flat, dog and half-dog points. Set screws have no head and feature a socket or slotted driver at one end. | • ASME B18.3 • DIN 913 / ISO 4026 • DIN 914 / ISO 4027 • DIN 915 / ISO 4028 • DIN 916 / ISO 4029 | |

| Titanium socket head cap screws are known as a safe reliable fastener in limited access situations where there is little clearance around the screws. They are also economic. | • ASME B18.3 • DIN 912 / ISO 4762 • DIN 7984 | |

| Vented screws are ideal for high vacuum fastening because the hole drilled through its axis (from head through threads) allows gases/contaminents to vent and relieve pressure. Titanium vented screws are available in any style. |

Titanium Bolts

| Titanium hex bolts are similar to hex head cap screws but without the added washer face. They are an economic solution to high clamping force applications with ease access. | • ASME B18.2.1 • DIN 931 / ISO 4014 • DIN 933 / ISO 4017 | |

| Titanium shoulder bolts are made up of a head, shoulder and threaded segment. The smooth shoulder section allows for rotating parts. Typically available with socket drivers. | • ASME • DIN 7379 / ISO 7379 • ISO 7370 | |

| Also referred to as anchor studs, Titanium wedge anchor bolts are an ideal solution when you need a high strength, corrosion resistant fastener to attach equipment and materials to concrete. |

Titanium Nuts

| Titanium hex nuts are available in a variety of styles including finished hex nuts, jam nuts and heavy hex nuts. | • ASME B18.16.3 • ASME B18.2.2 • DIN 439 / ISO 4035 • DIN 934 / ISO 4032 • DIN 986 | |

| Lock nuts are available in all metal (all metal, flexloc and stover) and polymer insert styles. All-metal titanium lock provide even load distribution and can be used at high temperatures. Polymer insert styles are more economical and are best for temperatures under than 350°F. | • ASME B18.16.3M • DIN 980 / ISO 7042 / ISO 19513 • DIN 6923 / ISO 4161 • DIN 985 / ISO 10511 / ISO 7040 |

Titanium Studs & Threaded Rod

| Titanium studs are fully threaded or partially threaded and made to custom lengths. | • ASME B18.31.2 • DIN 976 | |

| Titanium threaded rod or all thread are available in lengths greater than 1 foot. Minimum order quantity is a total of 6 of rod (1 x 6ft rod, 2 x 3ft rods, etc.). | • ASME B1.1 • DIN 975 | |

| Weld studs are available in both arc or capacitor discharge (CD) styles. Titanium weld studs provide an extremely secure fastening solution for permanent attachments with only one side accessible. |

Titanium Washers

| Titanium washers are stocked in SAE sizes, but also availabe in USS, oversized and custom sizes upon request. | • ASME 18.21.1 • SAE / USS • DIN 125 / ISO 7089 / ISO 7090 • DIN 126 / ISO 7091 | |

| Titanium split lock washer are available in stock. Belleville spring lock washers can also be made upon request. | • ASME B18.21.1 • DIN 127 / ISO 7090 • DIN 6796 / ISO 10690 |

Titanium Hose Clamps

Worm Drive Hose Clamp Worm Drive Hose Clamp | Titanium worm drive hose clamps offer an economic and resusable connection. | SAE |

Medium Duty Hose Clamps Medium Duty Hose Clamps | Titanium hose clamps feature a nut-and-bolt hose clamp with rolled band edges for the most secure, higher torque hold that is usable in both high and low pressure conditions. | SAE |