A high performace nickel alloy used for severe corrosion environments

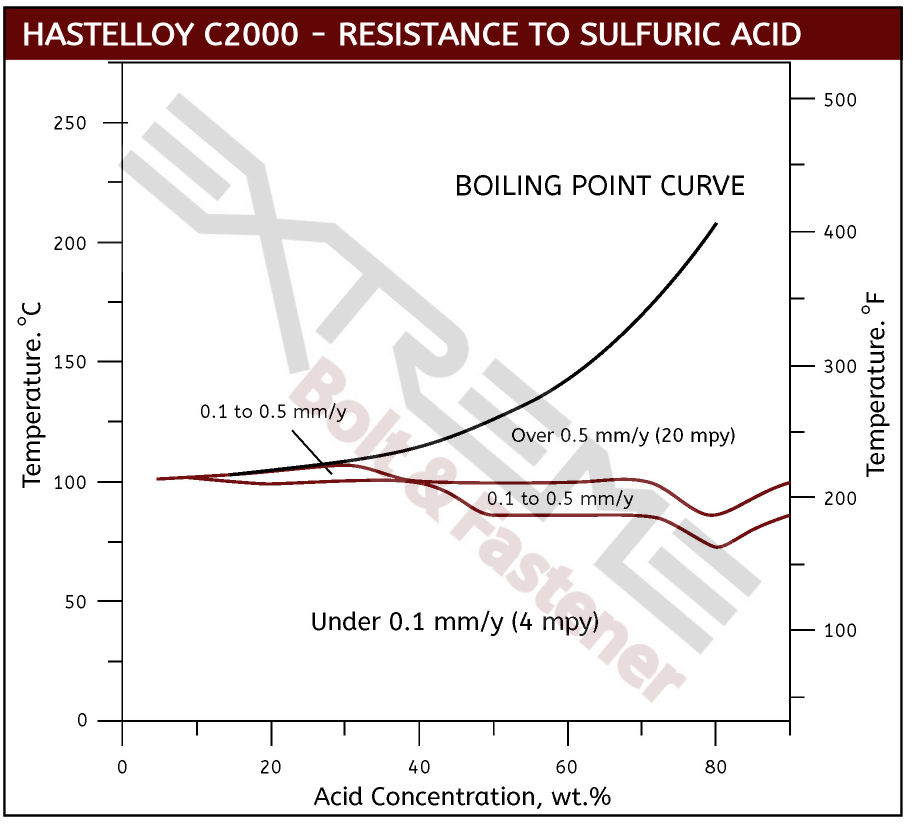

Hastelloy C2000 fasteners combine the outstanding resistance to oxidizing media of C276 with superior resistance to non-oxidizing environments, making it a unique alloy for protecting chemical process equipment across a wide range of conditions including streams contaminated with ferric ions. It was designed to offer greater versatility compared to the other Hastelloy alloys. This was accomplished by increasing the chromium and molybdenum content in addition to adding a small, but effective addition of copper (1.6%). The addition of copper provides C2000 fasteners enhanced temperature capability in sulfuric acid, hydrofluoric acid, and dilute hydrochloric acid. Click here for information on the chemistry and specifications of these high performance nickel alloy fasteners.

Availability: Hastelloy C2000 fasteners are generally available in 1/2" sizes and larger due to materials availability. Most C2000 fasteners are made to order.

Corrosion Performance

Key Benefits

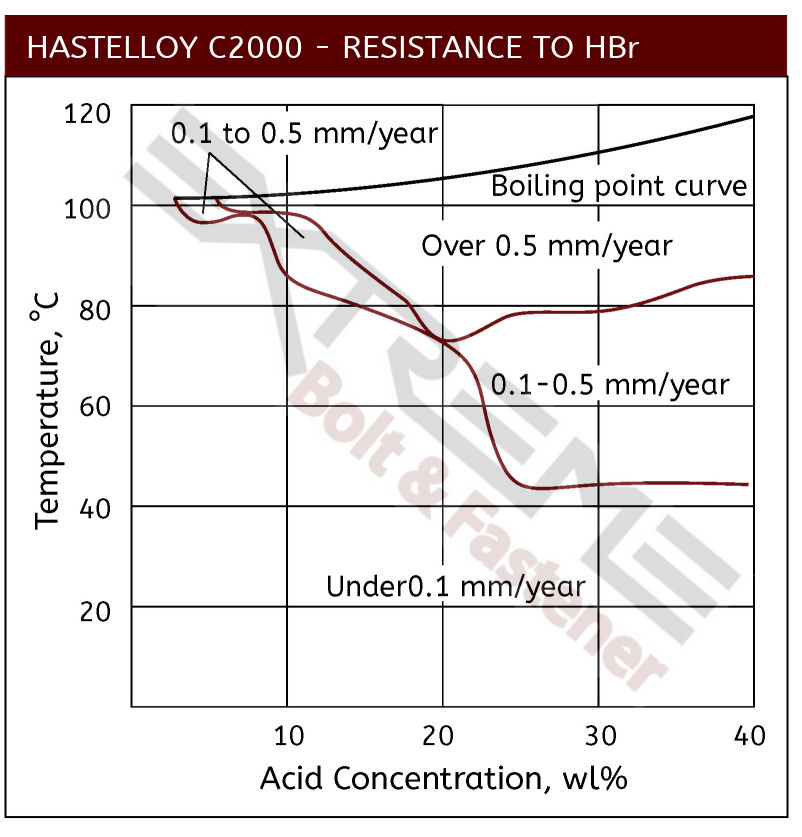

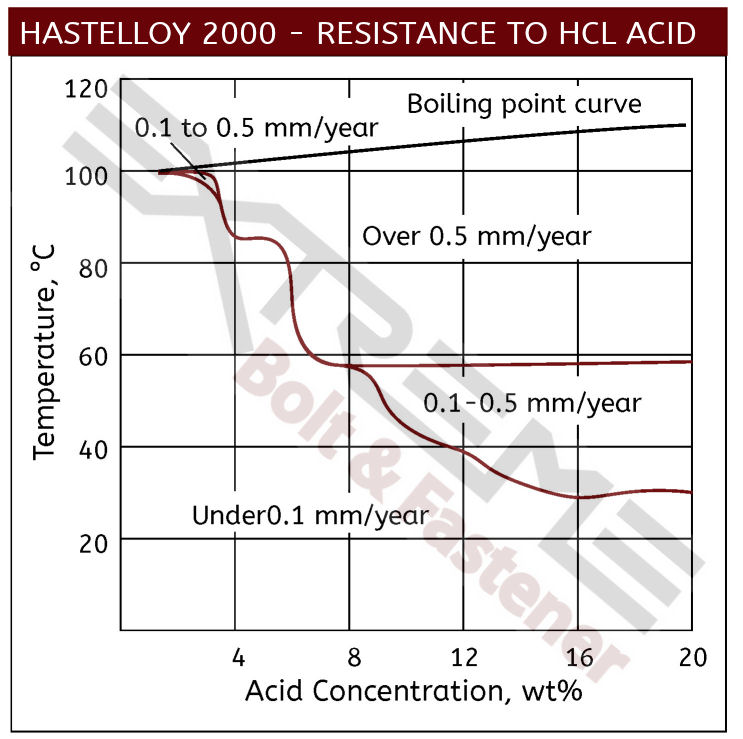

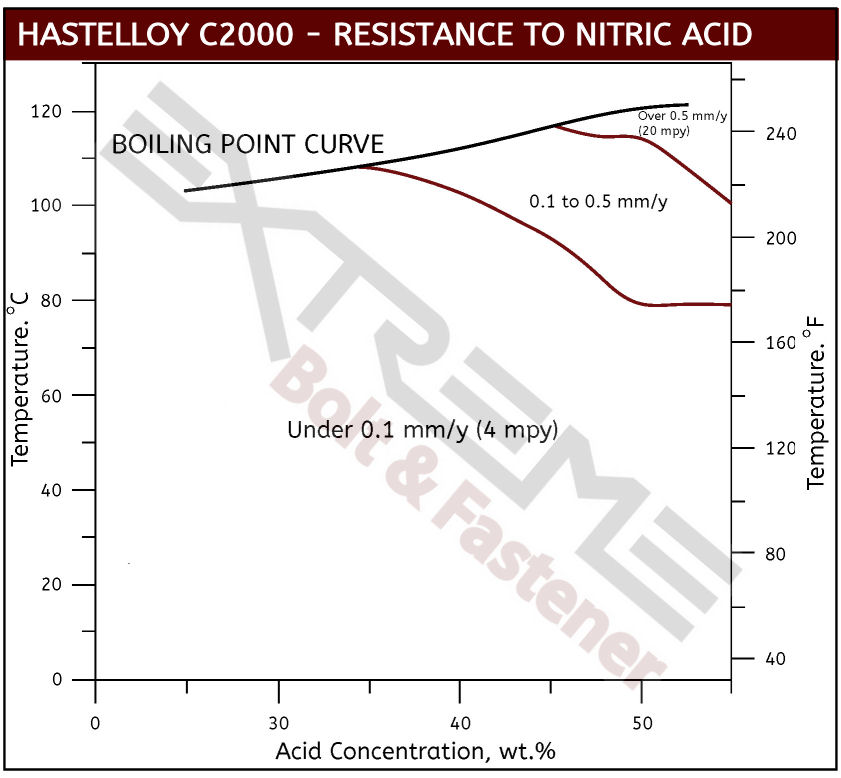

- Excellent resistance to all acids (especially hydrochloric, sulfuric, and hydrofluoric) over large temperature ranges

- Excellent protection from chlorides and other halide solutions, specifically pitting, crevice attack, and stress corrosion cracking

- Excellent resistance to stress corrosion cracking and superior resistance to localized corrosion compared to C-276

Uses

- Chemical process industry reactors, heat exchangers, columns, and piping

- Pharmaceutical industry reactors and dryers

- Flue gas desulfurization systems

Resources: Hastelloy Torque Spec, Flange Dimensions, Flange Bolting Chart

Hastelloy Fastener Types: Bolts, Nuts, Screws, Studs, Threaded Rods, Washers

Flange Types Available: Blind Flanges, Lap Joint Flanges, Slip On Flanges, Socket Weld Flanges, Threaded Flanges, Weld Neck Flanges

Hastelloy C2000 Fastener & Flange Grades & Chemistry

C2000 alloy, UNS N06200, is a corrosion resistant alloy with excellent resistance to uniform corrosion in oxidizing or re-ducing environments. Due to the addition of copper and the high content of chromium, it has enhanced corrosion resistance to sulfuric acid and process streams contaminated with ferric ions. In addition it has excellent resistance to stress corrosion cracking and superior resistance to localized corrosion as compared to C-276 alloy. This alloy has limited availability and can be made into sizes only 1/2" and greater is size for fasteners.

Hastelloy C2000 Specifications: SB 575/B 575, SB 574/B 574, SB 366/B 366 SB 462/B 462,SB 564/B 564 SB 462/B 462, NACE MR0175 ISO 15156, Werkstoff 2.4675

MECHANICAL PROPERTIES OF HASTELLOY

Hastelloy C2000 Sulfuric Acid Corrosion Performance

Hastelloy C2000 Hydrochloric Acid Corrosion Performance

Hastelloy C2000 Nitric Acid Corrosion Performance

Hastelloy C2000 Hydrobromic Acid Corrosion Performance