PVDF / Kynar Socket Head Cap Screws

Exceptional purity and chemical resistance with moderate strength

- High Purity and low extractables

- Chemically resistant to most common solvents including acids, salts, oils and steam

- Mechanical strength and toughness to 150°C (300°F)

- Resistance to ultraviolet, nuclear radiation, and standard sterilization methods

- Resistance to weathering and fungi

- Material datasheet for PVDF

- PVDF socket head cap screw features and benefits

PVDF socket head cap screws are made from a tough engineered fluoro-thermoplastic that offers a unique balance of excellent chemical resistance and good strength properties.

PVDF / Kynar® socket head cap screws have the characteristic stability of fluoropolymers when exposed to harsh chemical and ultraviolet environments but are much stronger mechanically than PTFE or PFA polymers. PVDF socket head cap screws are also excel in high purity and low-permeability applications such as pharmaceutical and semi-conductor processing.

PVDF socket head cap screws are available in most metric and standard sizes. See our online store (top right) for common sizes or contact us for your specific requirements.

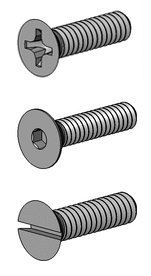

Screw Types: Flat Head Screws, Hex Cap Screws, Pan Head Screws, Set Screws, Socket Head Cap Screws

PVDF Socket Head Cap Screw Features and Benefits

When it comes to PVDF socket head cap screws, it’s all about clearance. These screws are the best choice for applications with limited installation access or clearance. Yet if you have an application with a lot of debris, you may want to select a PVDF hex head bolt or hex head cap screw, as they don’t have a socket drive which could get clogged.

Advantages:

- Ideal for applications with limited access as they require very little clearance around the fastener.

- Socket head cap screws can be used in locations where externally wrenched fasteners aren't desirable.

- Weight reduction on application as PVDF socket head cap screws are smaller – being that the cylindrical heads of socket screws need less space than hex heads and require no additional wrench space.

- Also known for safety, reliability and economy.

PVDF Mechanical & Physical Properties

|  |

PVDF Chemcial Resistance Compared to Other Polymers

(MATERIAL) Socket Head Cap Screws

When it comes to (material) socket head cap screws, it’s all about clearance. These screws are the best choice for applications with limited installation access or clearance. Yet if you have an application with a lot of debris, you may want to select a (material) hex head bolt or hex head cap screw, as they don’t have a socket drive which could get clogged.

Advantages:

Ideal for applications with limited access as they require very little clearance around the fastener.

Socket head can be used in locations where externally wrenched fasteners aren't desirable.

Weight reduction on application as (material) socket head cap screws are smaller – being that the cylindrical heads of socket screws need less space than hex heads and require no additional wrench space.

Also known for safety, reliability and economy.