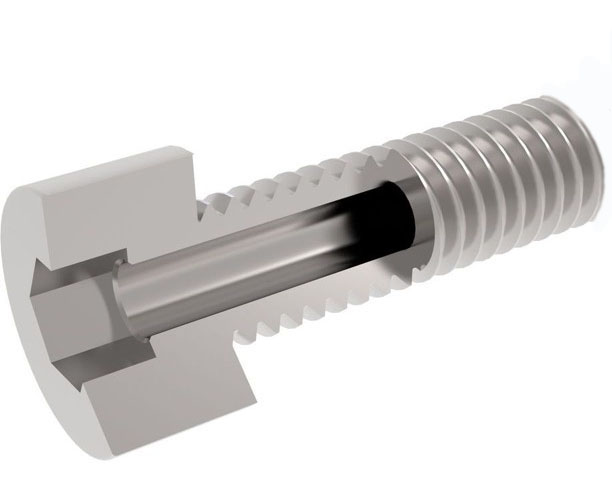

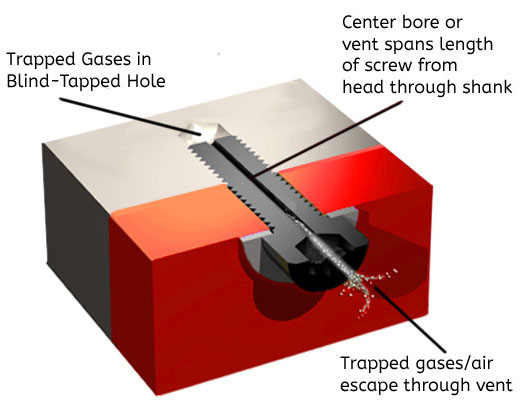

Vented screws are ideal for use in high vacuum (UV) and ultra high vacuum (UHV) equipment, as well as other high pressure environments and applications where gas pockets can form. Center vented screws have a center bore drilled through their axis from the head through the threaded shank of the screw. This feature provides an outlet for the complete evacuation of trapped air and gas contaminants to be pumped away from blind-tapped screw holes, bottoms, sides and shoulders. In addition to vented screws, washers with vent grooves can be made to ensure the venting of the cavity found under the screw head. Vented screws are ideal for use in high vacuum (UV) and ultra high vacuum (UHV) equipment, as well as other high pressure environments and applications where gas pockets can form. Center vented screws have a center bore drilled through their axis from the head through the threaded shank of the screw. This feature provides an outlet for the complete evacuation of trapped air and gas contaminants to be pumped away from blind-tapped screw holes, bottoms, sides and shoulders. In addition to vented screws, washers with vent grooves can be made to ensure the venting of the cavity found under the screw head.

Vented Screw Sizes

• #4 - 4"

• M3 - M100 | Availability

Both fine and coarse threads available | Vented Screws Benefits

• Enables faster, more efficient pump-down of HV & UHV systems

• Eliminates virtual leaks

• Relieves pressure from blocked gases

• Provides means to vent contaminants found in screw voids

• Promotes higher system throughput and improved yield

• Allows for constant pressure and temperature equalization

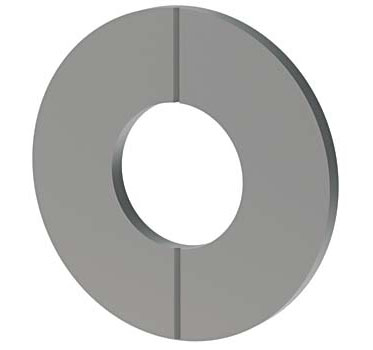

What is a vented washer?

When a screw is tightened over a flat washer, or directly an application without a washer, volumes of gas can be trapped in the space and beneath the fastener head along the screw shaft. Vented washers feature two bored canals on opposite sides of the flat face which provide an escape route for trapped gases. What is a virtual leak?

A virtual leak is comprised of gases that are trapped physically within a pocket with only a miniscule escape path from the trapped pocket of gas into the chamber proper.

|