An extremely strong precipitation hardened stainless steel

- Well suited for high strength applciaitons

- Up to 4x stronger than 316 stainless steel

- Maintains its mechanical strength up to 600°F

- 17-4PH Chemistry & Specifications

- ASTM F593 Gr 630

- ASTM A564 Gr 630

- 17-4PH vented screw features and benefits

- 17-4PH Datasheet

17-4 PH vented screws are made from a precipitation hardened stainless steel most known for its exceptional strength and its ability to maintain its mechanical properties to 600°F. Compared to 316 stainless steel, 17-4 PH vented screws yield strength is up over 4 times greater. When compared to Duplex 2205 screws, the yield strength of 17-4 PH can be up to 2-½ times greater.

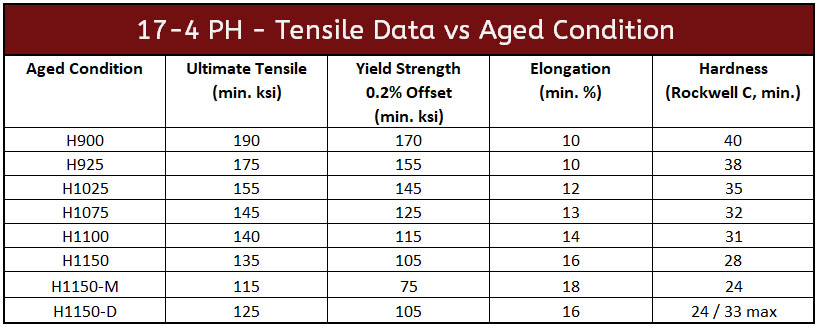

17-4 vented screws are available in 8 different aged (precipitation hardened) conditions offering a variety of mechanical properties (see below).

Resources: 17-4PH Torque Specs

17-4 PH Screw Types: 12 Point Screws, Button Head Cap Screws, Flat Head Screws, Hex Cap Screws, Pan Head Screws, Set Screws, Socket Head Cap Screws, Tamper Resistant Security Screws, Torx Screws, Vented Screws

17-4PH Vented Screw Features & Benefits

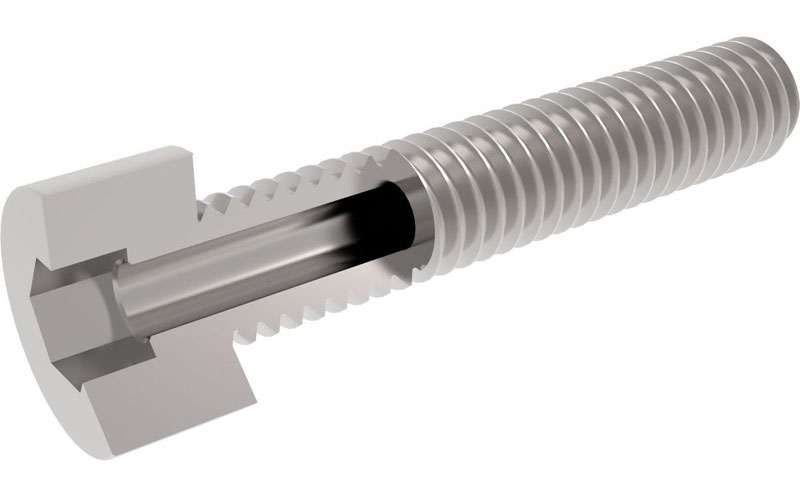

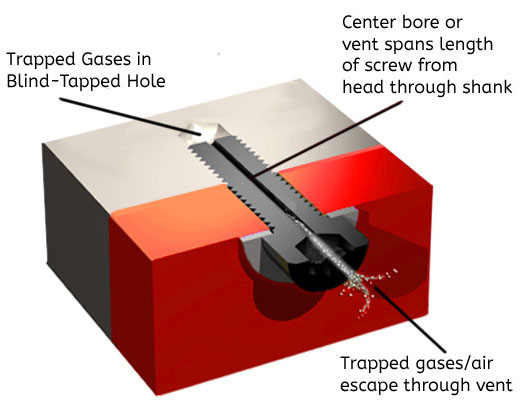

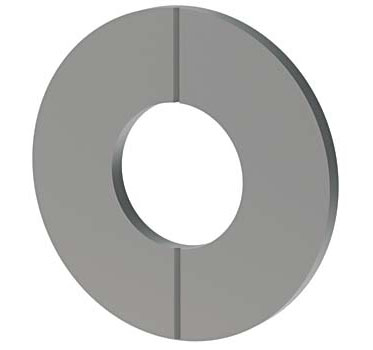

17-4PH vented screws are ideal for use in high vacuum (UV) and ultra high vacuum (UHV) equipment, as well as other high pressure environments and applications where gas pockets can form. Center vented screws have a center bore drilled through their axis from the head through the threaded shank of the screw. This feature provides an outlet for the complete evacuation of trapped air and gas contaminants to be pumped away from blind-tapped screw holes, bottoms, sides and shoulders. In addition to vented screws, washers with vent grooves can be made to ensure the venting of the cavity found under the screw head.

17-4PH Vented Screws Benefits

• Enables faster, more efficient pump-down of HV & UHV systems

• Eliminates virtual leaks

• Relieves pressure from blocked gases

• Provides means to vent contaminants found in screw voids

• Promotes higher system throughput and improved yield

• Allows for constant pressure and temperature equalization

17-4PH Vented Screws Are Available In:

• Socket Head Cap Screw

• Hex Head Cap Screw

What is a vented washer?

When a screw is tightened over a flat washer, or directly an application without a washer, volumes of gas can be trapped in the space and beneath the fastener head along the screw shaft. Vented washers feature two bored canals on opposite sides of the flat face which provide an escape route for trapped gases.

What is a virtual leak?

A virtual leak is comprised of gases that are trapped physically within a pocket with only a miniscule escape path from the trapped pocket of gas into the chamber proper.

17-4PH Chemistry & Specifications

17-4PH Specifications: UNS S17400, AISI 630, ASTM A564-630, Werkstoff 1.4542, AMS 5604 Sheet, Strip and Plate, ASTM A 693 Plate

ASTM F593, Grade 630

This specification covers seven groups of stainless steel alloys, with ASTM F593, Grade 630 applying 17-4PH. ASTM F593 Grade 630 covers the requirements for 17-4PH stainless steel bolts, hex cap screws, and studs sized 0.25 to 1.50 inches, inclusive, in nominal diameter. It is intended for common use and for service applications requiring general corrosion resistance.

Common 17-4 Fastener Conditions: Aged Conditions vs Tensile Strength

ASTM A564 GR 630

This specification covers bars and shapes (such as fasteners) of age hardened stainless steels such as 17-4PH. It includes hot-finished or cold-finished fasteners that are produced by hot rolling, extruding, or forging. Grade 630 shall be furnished in the solution-annealed or or age-hardened condition.