A-286 Slip On Flanges

A Fe-Ni-Cr alloy with excellent high temperature oxidation resistance

- Good material for high temperature oxidation resistance

- Maintains high strength at elevated temperatures

- A286 Chemistry, specs, and heat treatments

- Slip on flange features and benefits

A-286 slip on flanges are known for their high strength, creep resistance and oxidation resistance at elevated temperatures. This iron-nickel-chromium alloy (once age-hardened) provides A-286 slip on flanges with high levels of strength from room temperature up to about 1300°F (700°C).

A-286 slip on flanges are mildly corrosion resistant. While they should not be used for strong acid environments, they provide excellent oxidation resistance up to 1300°F (700°C) in conditions that would typically be found in high temperature exhaust streams.

Because of these properties, A-286 slip on flanges are often found in high temperature engine, manifold, exhaust and turbine applications as well as off-shore oil & gas applications.

Resources: A-286 Torque Specs, Flange Dimensions, Flange Bolting Chart

Flange Types Available: Blind Flanges, Lap Joint Flanges, Slip On Flanges, Socket Weld Flanges, Threaded Flanges, Weld Neck Flanges

A-286 Chemistry, Specifications & Heat Treatments

A-286 Heat Treatments: There are several heat treatment combinations for A-286 all with slight variations in performance. They can be specified via an AMS number or a 660 Class: A, B, C or D, with most common specified as class A or D. The A-286 grades A, B and C all have the same min tensile strength and min yield strength of 130ksi and 85ksi respectively. However grade D is significantly better yield with a min tensile of 130ksi and a min yield of 105ksi.

By AMS numbers, the most common for A-286 is AMS 5737 (same as Grade A) and then AMS 5732 (same as Grade B).

A-286 Specifications: AMS 5525, AMS 5732, AMS 5737, AMS 5804, EN 1.4980, GE B50T1181, GE B50T12, GE B50T81, UNS S66286, Werkstoff 1.4980

Mechanical Properties

A286 Slip on Flange Features & Benefits

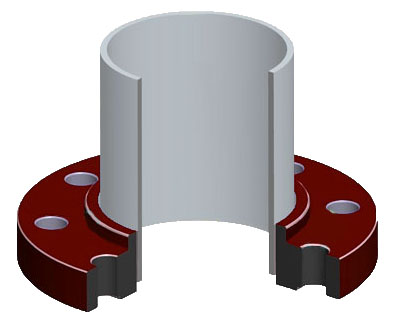

A286 slip on flanges are similar to the socket weld flange but without the socket shoulder. When using a socket weld flange, the pipe rests against this internal shoulder. Since a slip on flange does not have shoulder, the pipe can slide completely through the flange hub and is free to spin.

Advantages

- Typically lower in price than weld-neck flange, yet welding costs can be more.

- There is a reduced need to cut the pipe length accurately, making it easier to install.

- The slip on flange is free to spin on the pipe for easy bolt alignment.

Disadvantages

- They require two fillet welds: one fillet weld at the hub of the flange and a second weld at the inside diameter of the flange near the flange face.

- Though they can be used for high temperature and pressure applications, they typically are not as other flange types give a more secure joint.