Titanium Socket Weld Flanges

nique for its strength, lightness of weight and corrosion resistance

- Lightweight and high strength

- Corrosion resistant to chlorides, sea water & chlorine

- Excellent mechanical properties

- Titanium grades, chemistry & specifications

- In-depth information on Grade 2 and Grade 5

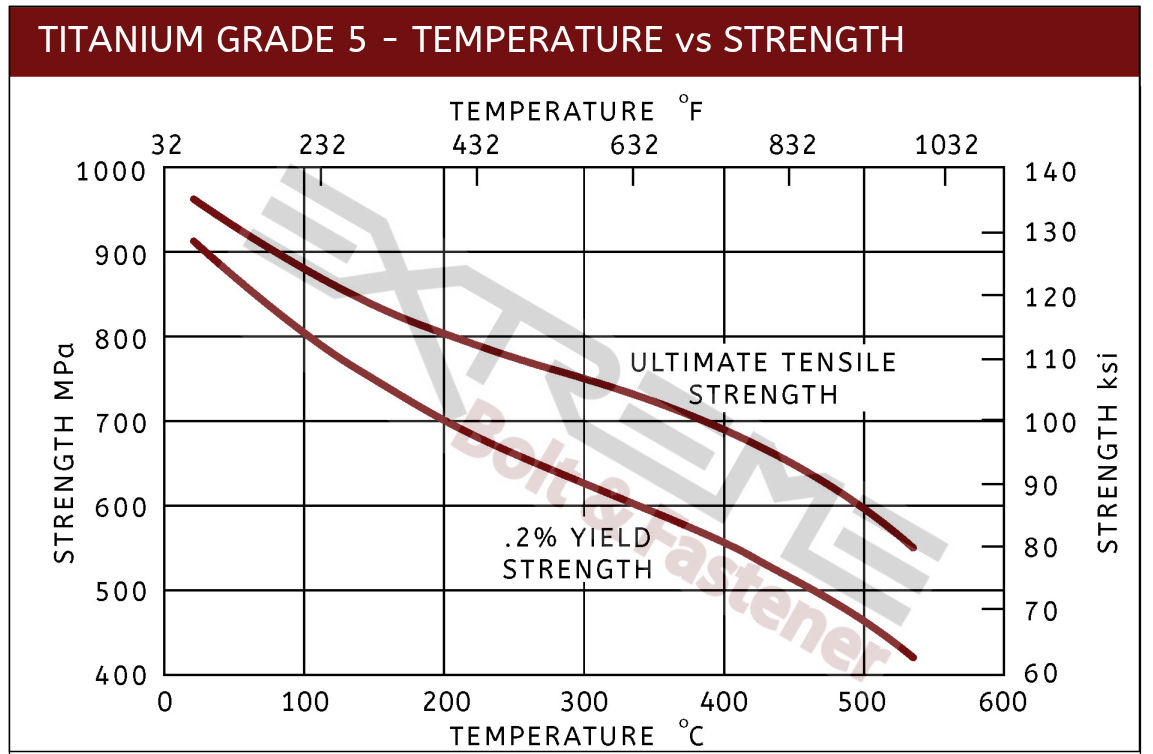

- Temperature vs strength data

- Socket weld flange features and benefits

Titanium socket weld flanges are best known for being strong, lightweight and corrosion resistant. One property that stands out when compared to other metal socket weld flanges is that titanium socket weld flanges have the highest strength-to-weight ratio with a density of 4.51 g /cm3. As an example, titanium grade 5 is 4 times stronger than 316 stainless steel at nearly half the weight. This makes titanium socket weld flanges ideal for applications that require both lightness of weight and excellent strength such as oil & gas (down-hole), military and sporting goods.

Titanium socket weld flanges are also unique among metals in the chemical processing industry for handling chlorine (wet) and chlorine compounds in aqueous solutions. Titanium socket weld flanges are fully resistant to solutions of chlorides, hypochlorites, chlorates, perchlorates and chlorine dioxide. As a result titanium socket weld flanges are often using within the chlorine related industries such as pulp and paper and chlor-alkali / bleach.

Titanium socket weld flanges are also an excellent material to prevent seawater corrosion. Because titanium socket weld flanges can resists corrosion by seawater up to temperatures as high as 500°F (260°C) as well as survive at ocean depths over a mile below the surface, titanium socket weld flanges are used throughout the oil & gas, desalination and marine industries.

The most common grades of Titanium threaded rods are Grade 2 and Grade 5. Gain more insight on these by accessing our Grade 2 and Grade 5 overviews or by contacting our engineering experts.

Resources: Titanium Torque Specs, Flange Dimensions, Flange Bolting Chart

Flange Types Available: Blind Flanges, Lap Joint Flanges, Slip On Flanges, Socket Weld Flanges, Threaded Flanges, Weld Neck Flanges

Titanium Grades, Chemistry & Specifications

Titanium Grade 2 (Commercially Pure)

Unalloyed titanium; Commercially pure titanium is the most common grade of titanium utilized throughout industry due to its ease of availability and good properties.

Titanium Grade 2 Specifications: UNS R50400, ASTM B 348, AMS 4921, ASTM F 67, ISO 5832-2, Werkstoff 3.7035

Titanium Grade 5 (Ti 6Al-4V)

Known as the “workhorse” of the titanium alloys, Ti 6Al-4V, or Grade 5 titanium, is 2x stronger than titanium grade 2. This alloy offers high strength and light weight, useful formability and high corrosion resistance. Ti 6AI-4V finds many uses in the aerospace, medical, marine and chemical processing industries.

Titanium Grade 5 Specifications: ASTM - B265, B348, B381, B861, F467 and F468, AMS - 4911, 4928, 4935, 4965 and 4967, MIL-T - 9046 and - 9047, Werkstoff 3.7165

Titanium Grade 7

Grade 7 is the most corrosion resistant of all titanium alloys and is typically used in chemical processes and production equipment components. Similar to Grade 2, but with the addition of 0.12 to 0.25% palladium, Grade 23 has enhanced corrosion resistance to reducing acids and localized attack in hot halides.

Titanium Grade 7 Specifications: ASTM - B265, B337, B338, B348, B363, B381, B861 and B862, Werkstoff 3.7235

Titanium Grade 23 (TI 6AL-4V ELI)

Titanium grade 23 or TI 6AL-4V ELI is an Extra Low Intersticial grade. This grade is similar to Grade 5, but because of the low intersticials, its mechanical properties are enhanced. This ELI grade is often found in more demanding medical device applications as well as industrial applications.

Titanium Grade 23 Specifications:

ASTM - B265, B348, B363, B381, B861, B862 andF136, AMS - 4907, 4930 and 4956

Other titanium grades are also available upon request.

Mechanical Properties

Titanium's Resistance to Chlorine

Corrosion Data

Titanium Grade 5 Temperature vs. Strength

Socket Weld Flange Features & Benefits

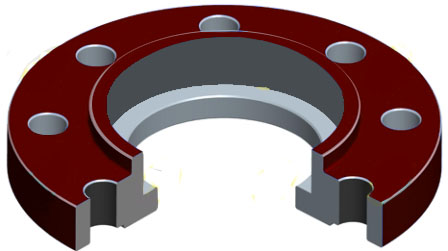

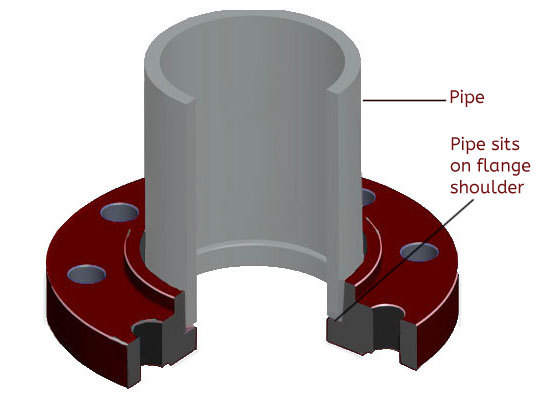

Similar to a slip on flange, an titanium socket weld flange has an added shoulder inside the bore hole. The socket weld flange is designed so that a pipe can be inserted into the socket of the flange until it hits the shoulder of the socket. The pipe is then backed away from the shoulder approximately 1/16 inches before being welded to the flange hub. This internal weld provides this type of flange added strength. In addition, by grinding the internal weld smooth, turbulence and flow restriction are minimized. Titanium socket weld flanges are most commonly used on small diameter applications (1/2" through 4") and high pressure piping systems.

Socket Weld Flange Benefits

- Best for small size, high pressure applications

- Static strength equal to a slip on flange yet boasts a fatigue strength 1.5 times that of the slip on design

- Employs both a backside hub weld and an internal shoulder weld for increased strength

- Socket weld flanges delivers a lower risk of leakage than threaded flanges

- Socket weld pipes do not have to be beveled for weld preparation

- Butt-welded joints are easily fitted and no special machining

Socket Weld Flange Disadvantages

- The expansion gap and internal crevices left in socket welded systems can promote crevice corrosion.

- Socket weld flanges have two welds which makes them stronger yet more labor intensive to install. Due to the increased welding, it has become the practice to weld only at the hub of the flange, which is not recommended.

Installation Tips

The socket weld pipe fittings should allow for expansion gap of 1/16 inch (1.6 mm) between pipe and the shoulder of the socket.