PVDF Threaded Flanges

Exceptional purity and chemical resistance with moderate strength

- High Purity and low extractables

- Chemically resistant to most common solvents including acids, salts, oils and steam

- Mechanical strength and toughness to 150°C (300°F)

- Resistance to ultraviolet, nuclear radiation, and standard sterilization methods

- Resistance to weathering and fungi

- PVDF material datasheet

- Threaded flange features and benefits

PVDF threaded flanges / Kynar® threaded flanges are made from a tough engineered fluoro-thermoplastic that offers a unique balance of excellent chemical resistance and good strength properties.

PVDF threaded flanges have the characteristic stability of fluoropolymers when exposed to harsh chemical and ultraviolet environments but are much stronger mechanically than PTFE or PFA polymers. PVDF threaded flanges also excel in high purity and low-permeability applications such as pharmaceutical and semi-conductor processing.

Resources: Flange Dimensions, Flange Bolting Chart

Flange Types Available: Blind Flanges, Slip On Flanges, Socket Weld Flanges, Threaded Flanges

PVDF Mechanical & Physical Properties

|  |

PVDF Chemcial Resistance Compared to Other Polymers

PVDF Threaded Flange Features & Benefits

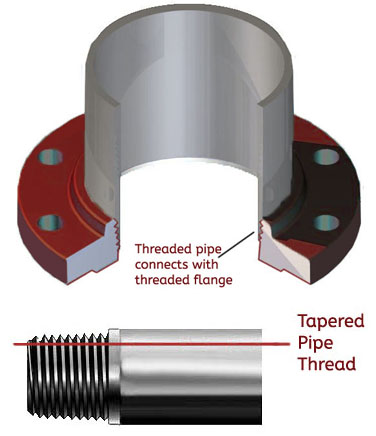

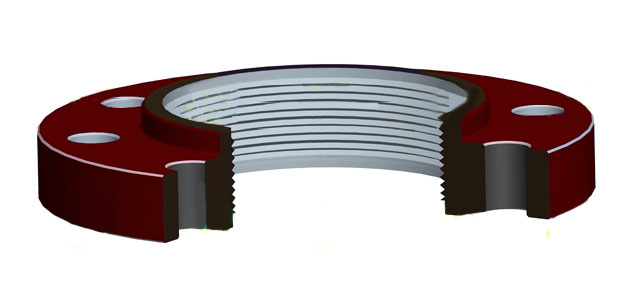

PVDF threaded flanges have a tapered female thread to join the male threads of a pipe in order to create a tight seal. This type of flange is most ideal when post weld heat treatment is not possible in hazardous, flammable or explosive applications where welding is too dangerous. PVDF threaded flanges are also convenient in pilot processes whose configuration is often changed.

Threaded Flange Advangtages

- The main benefit is that that threaded seal eliminates the need for welding.

- As they do not require welding they save time and money to install.

- Allow for connections to be made in dangerous, explosive applications where welding is not possible.

- Useful connection in materials that are difficult to create a successful and strong weld.

- Ideal for connecting small diameter pipes.

- Systems could be easily reconfigured.

Threaded Flange Disadvantages

- They are not suitable where high temperatures, frequent cyclic conditions or bending stresses are likely in applications.