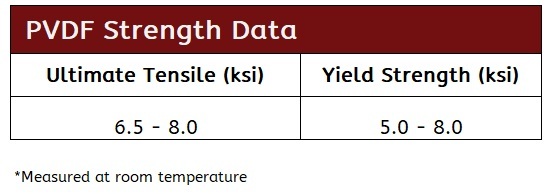

Exceptional purity and chemical resistance with moderate strength

- High Purity and low extractables

- Chemically resistant to most common solvents including acids, salts, oils and steam

- Mechanical strength and toughness to 150°C (300°F)

- Resistance to ultraviolet, nuclear radiation, and standard sterilization methods

- Resistance to weathering and fungi

- PVDF material datasheet

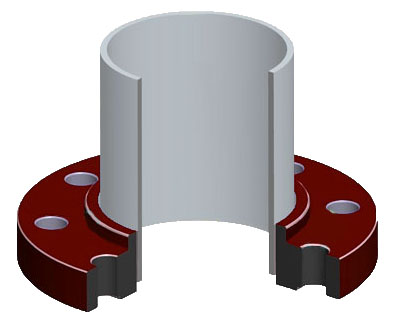

- Slip on flange features and benefits

PVDF slip on flanges / Kynar® slip on flanges are made from a tough engineered fluoro-thermoplastic that offers a unique balance of excellent chemical resistance and good strength properties.

PVDF slip on flanges have the characteristic stability of fluoropolymers when exposed to harsh chemical and ultraviolet environments but are much stronger mechanically than PTFE or PFA polymers. PVDF slip on flanges also excel in high purity and low-permeability applications such as pharmaceutical and semi-conductor processing.

Resources: Flange Dimensions, Flange Bolting Chart

Flange Types Available: Blind Flanges, Slip On Flanges, Socket Weld Flanges, Threaded Flanges

PVDF Mechanical & Physical Properties

|  |

PVDF Chemcial Resistance Compared to Other Polymers

PVDF Slip on Flange Features & Benefits

PVDF slip on flanges are similar to the socket weld flange but without the socket shoulder. When using a socket weld flange, the pipe rests against this internal shoulder. Since a slip on flange does not have shoulder, the pipe can slide completely through the flange hub and is free to spin.

Advantages

- Typically lower in price than weld-neck flange, yet welding costs can be more.

- There is a reduced need to cut the pipe length accurately, making it easier to install.

- The slip on flange is free to spin on the pipe for easy bolt alignment.

Disadvantages

- They require two fillet welds: one fillet weld at the hub of the flange and a second weld at the inside diameter of the flange near the flange face.

- Though they can be used for high temperature and pressure applications, they typically are not as other flange types give a more secure joint.