A Fe-Ni-Cr alloy with excellent high temperature oxidation resistance

- Good material for high temperature oxidation resistance

- Maintains high strength at elevated temperatures

- A286 Chemistry, specs, and heat treatments

- Threaded flange features and benefits

A-286 threaded flanges are known for their high strength, creep resistance and oxidation resistance at elevated temperatures. This iron-nickel-chromium alloy (once age-hardened) provides A-286 threaded flanges with high levels of strength from room temperature up to about 1300°F (700°C).

A-286 threaded flanges are mildly corrosion resistant. While they should not be used for strong acid environments, they provide excellent oxidation resistance up to 1300°F (700°C) in conditions that would typically be found in high temperature exhaust streams.

Because of these properties, A-286 threaded flanges are often found in high temperature engine, manifold, exhaust and turbine applications as well as off-shore oil & gas applications.

Resources: A-286 Torque Specs, Flange Dimensions, Flange Bolting Chart

Flange Types Available: Blind Flanges, Lap Joint Flanges, Slip On Flanges, Socket Weld Flanges, Threaded Flanges, Weld Neck Flanges

A-286 Chemistry, Specifications & Heat Treatments

A-286 Heat Treatments: There are several heat treatment combinations for A-286 all with slight variations in performance. They can be specified via an AMS number or a 660 Class: A, B, C or D, with most common specified as class A or D. The A-286 grades A, B and C all have the same min tensile strength and min yield strength of 130ksi and 85ksi respectively. However grade D is significantly better yield with a min tensile of 130ksi and a min yield of 105ksi.

By AMS numbers, the most common for A-286 is AMS 5737 (same as Grade A) and then AMS 5732 (same as Grade B).

A-286 Specifications: AMS 5525, AMS 5732, AMS 5737, AMS 5804, EN 1.4980, GE B50T1181, GE B50T12, GE B50T81, UNS S66286, Werkstoff 1.4980

Mechanical Properties

A286 Threaded Flange Features & Benefits

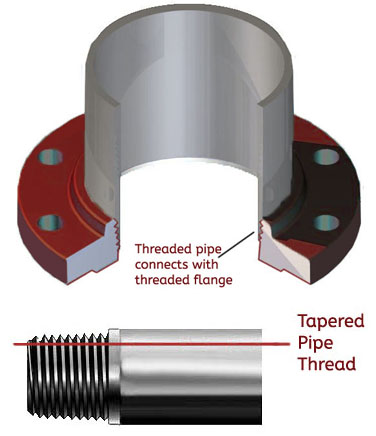

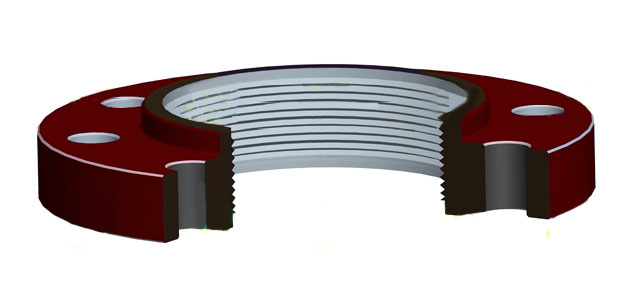

A286 threaded flanges have a tapered female thread to join the male threads of a pipe in order to create a tight seal. This type of flange is most ideal when post weld heat treatment is not possible in hazardous, flammable or explosive applications where welding is too dangerous. A286 threaded flanges are also convenient in pilot processes whose configuration is often changed.

Threaded Flange Advangtages

- The main benefit is that that threaded seal eliminates the need for welding.

- As they do not require welding they save time and money to install.

- Allow for connections to be made in dangerous, explosive applications where welding is not possible.

- Useful connection in materials that are difficult to create a successful and strong weld.

- Ideal for connecting small diameter pipes.

- Systems could be easily reconfigured.

Threaded Flange Disadvantages

- They are not suitable where high temperatures, frequent cyclic conditions or bending stresses are likely in applications.