The optimal balance of chemical, mechanical and thermal properties

The optimal balance of chemical, mechanical and thermal properties

- Excellent strength, and stiffness up to 500°F (260°C)

- Low coefficient of friction and high wear resistance

- Chemically resistant to common chemicals

- Low out gassing, low particle generation and inherent purity

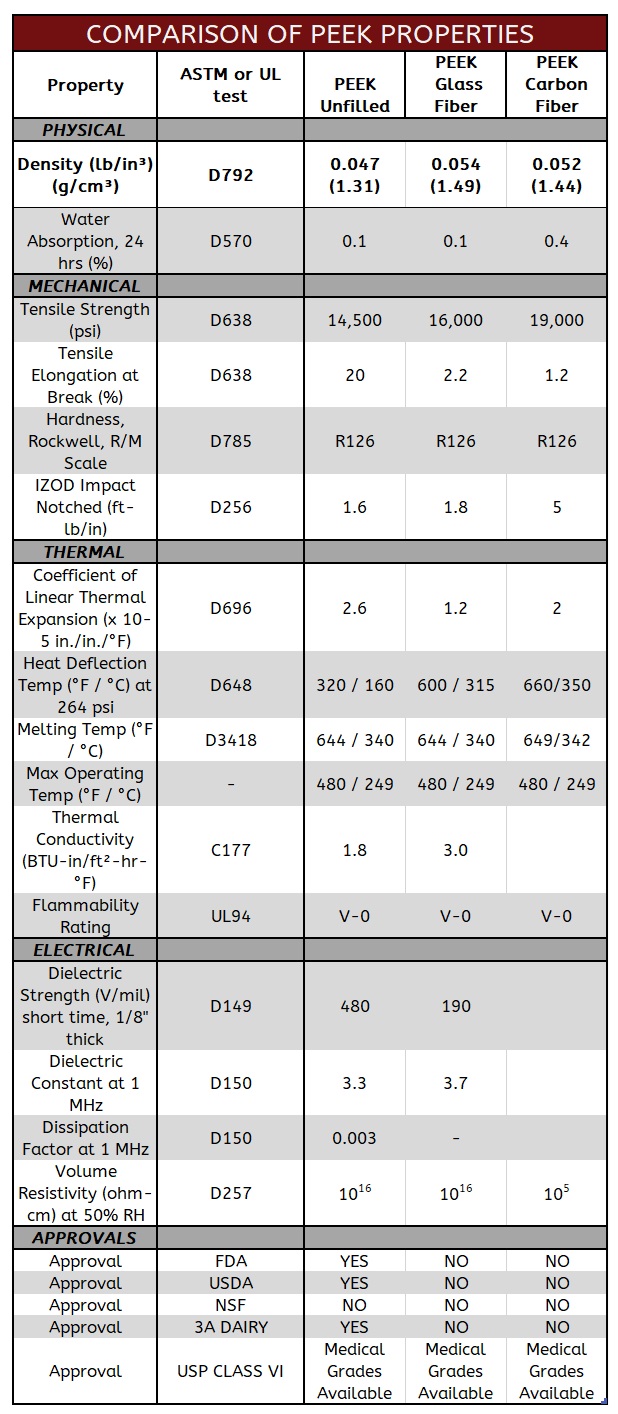

- Unique physical, thermal & electrical properties

- PEEK fastener styles

- Stock and availability of PEEK fasteners

- Custom injection molded & machined parts

- PEEK material datasheet

PEEK fasteners (chemically known as Polyetheretherketone) offer a unique combination of properties for some of the most extreme applications. PEEK is classified as semicrystalline thermoplastic and high purity polymer, offering excellent mechanical strength and chemical resistance at high temperatures. PEEK fasteners offer a high strength alternative to PTFE fluoropolymers.

Key Benefits

- Excellent resistance to thermal degradation (chemical decomposition caused by heat).

- Chemically resistance to many oils, alcohols, solvents, and organics as well as harsh acids and bases in low concentrations and temperatures.

- Hydrolysis resistance provides PEEK ability to retain all physical properties when continuously exposed to water or steam at high temperatures and pressures, as well as offer very low moisture absorption.

- Outstanding creep resistance allows PEEK fasteners to sustain large stresses over long service life.

- Ability to withstand frequent sterilization processes.

- V-0 flammability rating with low smoke and toxic gas emission when exposed to flame.

- Good wear and abrasion resistance.

- Electrical properties are maintained over a wide frequency and temperature range.

- Radiation resistance allows PEEK to be used in or be repeatedly sterilized by, high doses of ionizing radiation.

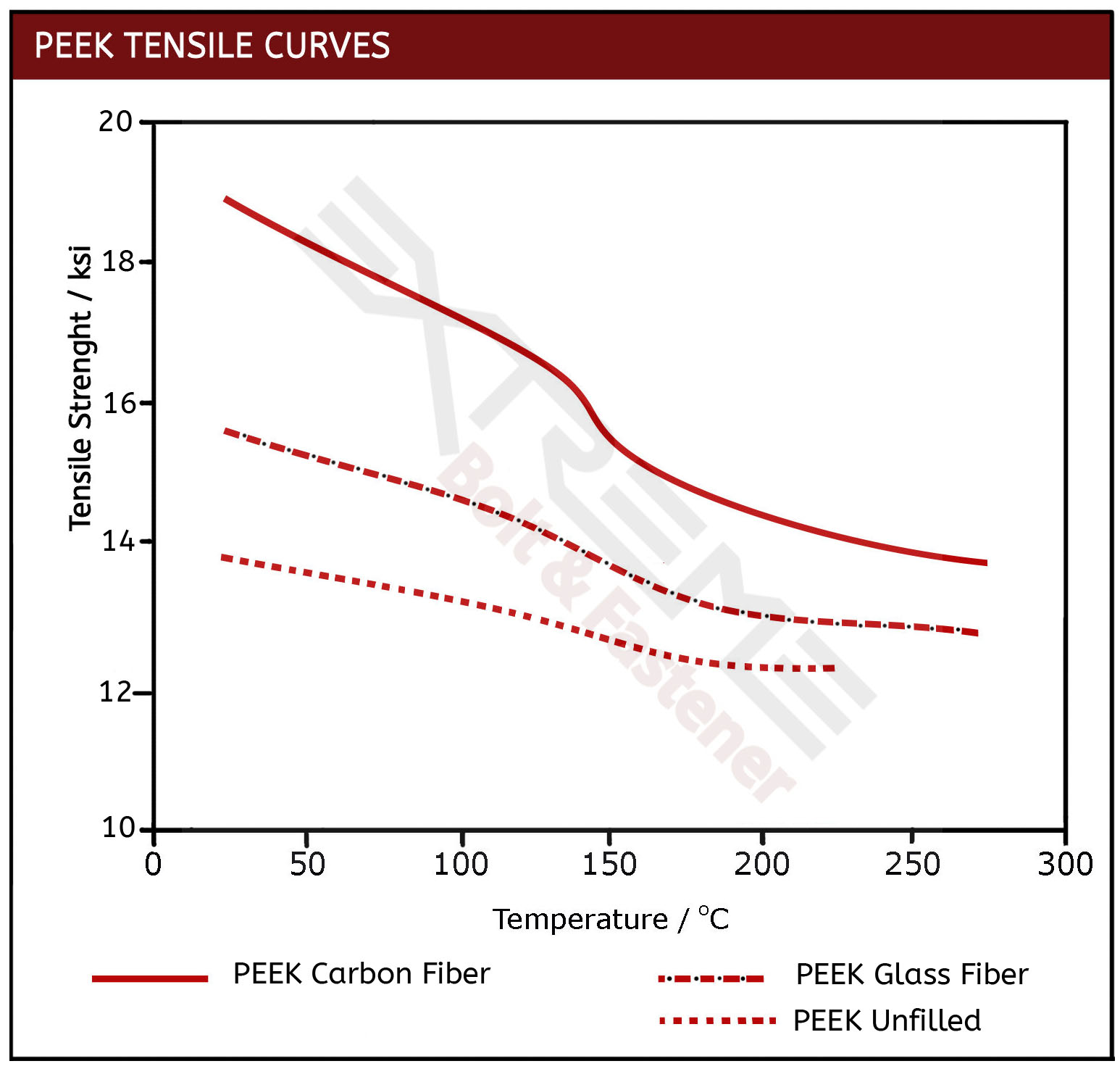

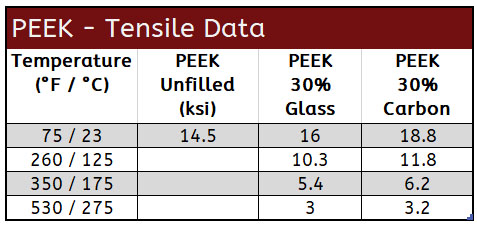

Options for High Strength

Depending on the application, PEEK screws can be reinforced with glass or carbon fibers for improved strength and stiffness properties. Reinforced PEEK fasteners offer greater mechanical robustness especially in applications beyond 350°F (175°C).

PEEK 100% / Unfilled

PEEK, with no fillers is unreinforced and 100% polymer. Even without glass or carbon fiber reinforcement, this one of the strongest polymers we offer and well suited for a variety of applications including FDA food contact and other applications requiring high purity.

PEEK Glass Fiber Reinforced

Offers the same chemical resistance as natural PEEK, but also offers increased strength by about 10%. Note, elongation will greatly decrease due to the glass fibers. ***See Note Below.

PEEK Carbon Fiber Reinforced

Provides approximately a 30% increase in strength of pure PEEK. PEEK fasteners with carbon fiber have low elongation and will be electrically conductive. ***See Note Below.

***NOTE: The strength data listed for both PEEK Glass Fiber and PEEK Carbon Fiber fasteners may be significantly less than published values from polymer manufacturers. Normally published data is created from perfect injection molded tensile samples. As most fiber reinforced fasteners are machined from extruded bar stock (not injection molded), fibers are cut when manufactured, sharp angles of fasteners create stress risers, and the orientation of the fibers within the extruded bar are typically perpendicular to the length of the fastener.

As a result, the published values from the polymer manufacturers of these materials are much higher than the ACTUAL values you may expect. The values we have noted on this site are what one might TYPICALLY see in use when the fasteners are machined from bar stock.

Applications

- Viewed by the medical community as an advanced biomaterial, PEEK fasteners are used in medical implants and are compatible with a high-resolution magnetic resonance imaging (MRI).

- PEEK fasteners are one of the few plastics compatible with ultra-high vacuum (UHV) which is necessary for many analytic techniques and particle accelerators.

- Chemical processing and pharmaceutical applications depend on PEEK for it’s chemical resistance, high purity and ability to withstand sterilization processes.

- PEEK fasteners are used in many electronics from cell phones to circuit boards for their lightweight strength and reduced noise, vibration and harshness (NVH).

PEEK Fastener Stock and Availability

Stock

PEEK screws, bolts, nuts and washers are available and ready to ship in many common sizes. You can purchase many of these directly from our online webstore. In addition, we stock other PEEK fasteners. Please contact us for a specific size and part you need.

Custom Availability

PEEK screws and fasteners can be made to order in many different styles and sizes with minimum quantities, typically around 25 pieces. Fasteners can be produced in pure PEEK, glass-filled PEEK, carbon-filled PEEK and PEEK Extreme. We also have the capability to produce unique, per-print custom fasteners. The normal lead time for custom PEEK fasteners about 4 weeks. Be sure to contact us for specific lead times and expediting needs.

• Diameter sizes: Standard #00 – 4” in diameter / Metric M1.2 – M48

• Threads: UNC, UNF

• Minimum Volume – Typically 25pcs depending on size and complexity

• Custom to print

• All DIN / ISO standards

Expediting Options

When time is critical, we can help. When requesting a quote, please let us know your lead time requirements so that we can do our best to accommodate your needs.

PEEK Fastener Styles

| PEEK Screws | Button Head Cap Screws, Flat Head Screws, Hex Head Cap Screws, Pan Head Screws, Set Screws, Socket Head Cap Screws |

| ||

| PEEK Bolts | Hex Head Bolts |

| ||

| PEEK Nuts | Hex Nuts | • DIN 439 / ISO 4035 • DIN 934 / ISO 4032 • DIN 6923 / ISO 4161 | ||

| PEEK Studs/Rod | Studs, Threaded Rod | • DIN 975 • DIN 976 | ||

| PEEK Washers | Flat Washers | • DIN 125 / ISO 7089 / ISO 7090 • DIN 126 / ISO 7091 • DIN 9021 / ISO 7093 |

Mechanical Properties of PEEK

|  |

Chemical Resistance of PEEK / Victrex® Fastener

PEEK Properties

PEEK Screws

| | PEEK button head screws typically feature a socket driver and offer a wide clamping area and low profile. They are best for fastening material that is too thin to counter bore. | • ASME B18.3 • ASME 18.3.4M • DIN 7380 / ISO 7380 |

| | PEEK flat head screws are commonly offererd in a 82° countersink angle, but can be custom made to other angles from 60° -120°. Typically PEEK flat heads have a slotted or phillips drive, but can also be custom made with a socket drive. These screws are designed to be flush with the surface. | • ASME B18.3 • ASME B18.3.6 • DIN 963 / ISO 2009 • DIN 965 / ISO 7046 • DIN 7991 / ISO 10642 |

| PEEK hex head cap screws feature an added washer face to the bolt head a hex head bolt does not have. Hex head cap screws provide tighter dimensional tolerances over hex bolts. PEEK hex head screws are best for applications that need a high clamping force with easy access. Generally available in #2 - 1/2" sizes and metric sizes. | • ASME B18.6.3 • DIN 931 / ISO 4014 • DIN 933 / ISO 4017 • DIN 961 / ISO 8676 | |

| Featuring either a slotted or phillips drive, PEEK pan head screws have a rounded head and are best for small diameter fastener needs, as well as low torque applications. | • ASME B18.6.3 • DIN 7985 • DIN 921 • DIN 85 / ISO 1580 • DIN 84 / ISO 1207 (cheese head) • DIN 966 / ISO 7047 (raised counter sunk) | |

| PEEK set screws are custom made with a cup, cone, flat, dog or half-dog point. Set screws have no head and feature a socket or slotted driver at one end. | • ASME B18.3 • DIN 913 / ISO 4026 • DIN 914 / ISO 4027 • DIN 915 / ISO 4028 • DIN 916 / ISO 4029 | |

| PEEK socket head cap screws provide a safe reliable fastener in situations where there is limited access or little clearance around the screws. They are also economic. | • ASMET B18.3 • DIN 912 / ISO 4762 • DIN 7984 |

PEEK Bolts

| Similar to hex head cap screws, PEEK bolts do not have the added washer face. They are an economic solution to high clamping force applications with easy access. | • ASME B18.2.1 • DIN 931 / ISO 4014 • DIN 933 / ISO 4017 |

PEEK Nuts

| | Most common sizes of PEEK hex nuts are stocked and ready to ship. Custom sizes can also be made upon request. | • ASME B18.16.3 • ASME B18.2.2 • DIN 439 / ISO 4035 • DIN 934 / ISO 4032 • DIN 986 |

PEEK Studs & Threaded Rod

| PEEK studs are fully threaded or partially threaded rodsare less than 12" in length. They can be made to any custom length. | • ASME B18.31.2 • DIN 976 | |

| PEEK threaded rods are available in lengths greater than 1 foot. The minimum order quantity is a total of 6 of rod which can be cut as one- 6ft rod, two-3ft rods, etc. | • ASME B1.1 • DIN 975 |

PEEK Washers

| Many sizes of PEEK washers are in stock and ready to ship. PEEK washers are available per SAE, USS, and oversized, as well as custom sizes upon request. | • ASME 18.21.1 • SAE / USS • DIN 125 / ISO 7089 / ISO 7090 • DIN 126 / ISO 7091 |