A high performace nickel alloy used for severe corrosion environments

- Excellent corrosion resistance to reducing and oxidizing environments

- Well suited for hydrochloric and sulfuric acid environments

- Strong resistance to stress corrosion cracking

- Excellent mechanical properties at elevated temperatures

- Alloy grades: C276, B2, B3, C22, Hastelloy X

- Hastelloy flat head screw features and benefits

Hastelloy® flat head screws are in stock and available now - such as Hastelloy C276, which is generally considered a versatile and highly corrosion resistant alloy. Hastelloy screws have excellent corrosion resistance in both oxidizing and reducing media which makes it well suited for a variety of strong corrosive applications. Hastelloy flat head screws also have exceptional resistance to both sulfuric acid and hydrochloric acid.

Because Hastelloy screws resist some of the most severe media, Hastelloy flat head screws are often utilized in chemical processing applications where acid chlorides, solvents, formic and acetic acids, acetic anhydride, wet chlorine gas, hypochlorites, chlorine solutions and phosphoric acid are used. For chemical processing applications, Hastelloy C276 is the most common grade and one of the most corrosion resistant nickel alloys - exceeding that of most other nickel alloy grades like Inconel or Monel. For more indepth material information download our Hastelloy C276 datasheet.

Resources: Hastelloy Torque Spec

Screw Types: 12 Point Screws, Button Head Cap Screws, Flat Head Screws, Hex Cap Screws, Pan Head Screws, Set Screws, Socket Head Cap Screws, Tamper Resistant Security Screws, Torx Screws

Hastelloy Flat Head Screw Features and Benefits

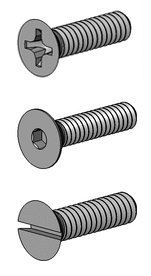

Hastelloy flat head screws are characterized by having a head with a top flat surface (which can feature either a slotted, phillips or allen driver) and bottom that is cone shaped or countersunk. With this design, the head of the screw can align flush or below the surrounding surface having obvious benefits.

Hastelloy Slotted vs. Phillips Driver

| Slotted Head Advantages | Phillips Head Advantages |

|

|

Countersink Angle

For most flat head screw designs the angle of countersink is usually 82° for UNC and UNF applications however other angles ranging from 60° -120° could be specified.

| Thread Type | Normal Flat Head Countersink Angle |

UNC / UNF | 82° |

| Aerospace | 100° |

| ISO Metric / Imperial | 90° |

Common Hastelloy Bolt Grades

Confused about which grade of Hastelloy bolts are best for your corrosive application? Read this short blog post which gives an overview of each grade's strength. If you need more indepth direction, visit our Hastelloy grade pages or contact our engineering team.

Hastelloy C276 alloy, UNS N10276, is the most widely used and versatile, corrosion resistant alloy. Very good resistance to reducing, and mildly oxidizing corrosives. Excellent stress corrosion cracking resistance with very good resistance to localized attack. For more indepth material information download our Hastelloy C276 datasheet.

Hastelloy C276 Specifications: N10276, ASTM B574, ASME SB574, Werkstoff 2.4819, ASTM G28-A/B, EN 10204-3.1, ASME B18.2.2, ASTM B619, ASME SB619, ASTM B366, ASME SB366, WPHC276, ASME B16.11, ASTM B564/ASME SB564, COLD DRAWN, HOT FINISHED, ASTM B575, ASME SB575, COLD ROLLED, HOT ROLLED, ASME B16.9, ASME B16.5, ASTM B462, ASME SB462

Hastelloy B3 alloy, UNS N10665, resistance to hydrochloric acid and other strongly reducing chemicals but has poor corrosion resistance to oxidizing chemicals and in the presence of ferric or cupric salts. In addition, Hastelloy B2 has excellent resistance to pitting and stress corrosion cracking. However B2 has little chromium, and it should NOT be used with oxidizing media in the presence of salts. Select the following links for more details about Hastelloy B2 Bolts, Screws, and Flanges.

Hastelloy B2 Specifications: N10665, ASTM B619, Werkstoff 2.4617, ASME SB619, ANNEALED, B/SB619 CLASS I OR II, X-RAY PER ASME SECTION VIII DIVISION 1 UW-51, MERCURY FREE, EN 10204-3.1, ASTM B366, ASME SB366, WPHB2-S, ASME B16.11, ASTM B335, ASME SB335, ASME B16.3, MSS SP-83, ASTM B564/ASME SB564, COLD DRAWN, HOT FINISHED, ASTM B333, ASME SB333, SHEET IS COLD ROLLED, HOT ROLLED, ENIMO-7, AWS A-5.11, ASME SFA-5.11

Hastelloy B3 alloy, UNS N10675, is specifically designed to deal with very aggressive hydrochloric acid (HCl), hyrdrobromic acid (HBr) and sulfuric acids (H2SO4) as well as acetic, formic and phosphoric acids. Additionally Hastelloy B3 has improved structural integrity over B2. However B3 has little chromium, and it should NOT be used with oxidizing media in the presence of salts. Select the following links for more details about Hastelloy B3 Bolts, Screws, and Flanges.

Hastelloy B3 Specifications: N10675, ASTM B366, ASME SB366, Werkstoff 2.4600, WPHB3-W, ASME B16.9, ANNEALED, MERCURY FREE, EN 10204-3.1 (W/O X-RAY), ASTM B335, ASME SB335, ASTM B564, ASME SB564, DIMENSIONS PER ASME B16.5, ASTM B462, ASME SB462, ASME B16.5, COLD DRAWN, HOT FINISHED, ASTM B626, ASME SB626, B/SB626 CLASS III, ASTM B333, ASME SB333, COLD ROLLED, HOT ROLLED

Hastelloy C22 alloy, UNS N06022, has better overall corrosion resistance in oxidizing corrosives than C-276 and Inconel 625 alloys due to the higher chromium content. Outstanding resistance to localized corrosion and excellent resistance to stress corrosion cracking. This alloy has limited availability and can be made into fastener in larger diameters only (1/2" and greater in size). Select the following links for more details about Hastelloy C22 Bolts, Screws, and Flanges.

Hastelloy C22 Specifications: SB 575/B 575, SB 574/B 574, SB 366/B 366 SB 462/B 462, SB 564/B 564 SB 462/B 462, Werkstoff 2.4602, 17744 No. 2.4602 NiCr21Mo14W, NACE MR0175 ISO 15156

Hastelloy C2000 alloy, UNS N06200, is a corrosion resistant alloy with excellent resistance to uniform corrosion in oxidizing or re-ducing environments. Due to the addition of copper and the high content of chromium, it has enhanced corrosion resistance to sulfuric acid and process streams contaminated with ferric ions. In addition it has excellent resistance to stress corrosion cracking and superior resistance to localized corrosion as compared to C-276 alloy.

Hastelloy C2000 Specifications: SB 575/B 575, SB 574/B 574, SB 366/B 366 SB 462/B 462,SB 564/B 564 SB 462/B 462, Werkstoff 2.4675, NACE MR0175 ISO 15156

Alloy X, UNS N06002, is most known for its exceptional combination of high temperature oxidation resistance up to 2000°C and high temperature strength. Being stable, strong and ductile at high temperatures are its most notable characteristics which is often utilized in gas turbine components and furnace components.

Hastelloy X Specifications: AMS 5536, AMS 5754, AMS 5798, ASME SB 435, ASME SB 572, ASME Sect. IX P No. 43, ASME Section IX P No. 43, ASME SFA 5.14, ASTM B 435, ASTM B 572, EN 2.4665, GE B50A436, GE B50T83, GE B50TF24, PDS 1038 (X-low), PDS 15102QFC, UNS N06002, Werkstoff 2.4665

MECHANICAL PROPERTIES OF HASTELLOY

|

|

|

|

|

|

Hastelloy Corrosion Data