Best Thread for Your Specific Needs

Bolt threading has a huge impact on the performance of a fastener. There are many options when it comes to threading. But let start with the basics and explore the different threading options Extreme Bolt offers. Fine and Coarse Threads Coarse threads are denoted by the standard UNC. A bolt with coarse threads has less threads per inch than a fine thread – so the threads are further apart. Coarse threads work for most applications and are the most common. In contrast, fine threads offer more threads per inch. They are denoted by the standard UNF. Bolts with fine threads provide more grip as the threads are closer together and there are more threads to hold the bolt in place. Fine threads are typically required for applications that require greater security and tighter tolerances. Understanding Thread Tolerance and Classes

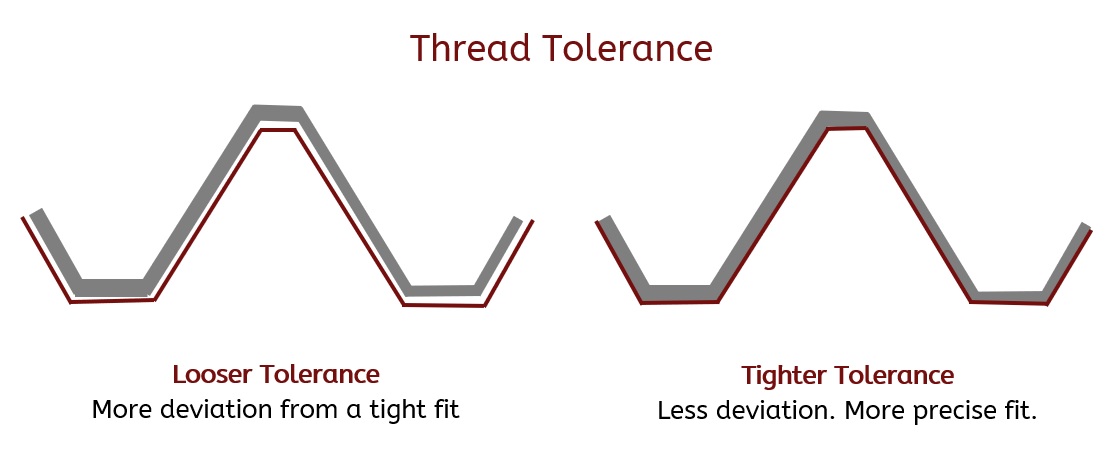

Threads are categorized into 3 classes that denote the thread tolerance for the pitch: 1, 2 and 3. Class 1 has the loosest tolerance whereas 3 has the most precise. Class 2 is often most common for standard applications. In addition to the classes, there are letters assigned to denote internal verses external threads. The letter A is assigned to external threads so threading on bolts, screws, rod and studs: classes are 1A, 2A and 3A. The letter B is assigned to internal threading for nuts, which include 1B, 2B and 3B.

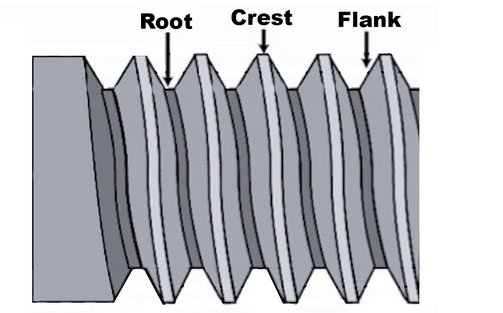

Rolled Threads Compared to Machined Threads Machined threads refer to the internal root and flank of the thread being cut away to create the thread form. In contrast, rolled threads means the threads are formed by pressing the parts between two round dies or flat plates that already have the thread pitch machined onto their face. When the parts move, or roll, through the dies, the threads are formed by the applied pressure without cutting or removing any material.

When threads are rolled, it creates a rounded root radius. Also, the cold working process of the thread rolling operation increases the strength of the material within the threads. For non-heat-treated bolts – rolled threaded parts have higher strengths than cut threads in the area where the thread was formed. However, for heat treated parts, rolled or cut threads have the same strength as the heat treatment dictates the strength. Therefore, rolled threads are a way off adding strength to the threads in non-heat treated materials. Specialty Threads The only difference between UNC threads and UNRC threads (or UNF and UNRF threads) is that the root of the thread – the valley that is between the thread “peaks” – is curved/rounded rather than angular. These roots are rounded with an approximate curvature between 0.108 and 0.144 times the pitch. The UNRC and UNRF makes the roundness between threads mandatory, whereas with the UNC and UNF threads the roundness is optional. The reason UNRC threads are produced is because this rounded root helps to improve fatigue strength. UNR stands for unified rounded thread. UNC and UNRC threads are compatible. So, if you are mixing a UNC nut with a UNRC bolt – the threads will still maintain a proper fit. “J” Pitch Threads The biggest trick about J threads is that internal J threads on a nut can be used with standard UNC or UNF threaded bolts, whereas the reverse is not the case. Remember you CANNOT use an external J threaded bolt, screw or stud with a standard threaded nut due to the interference at the minor diameter. | Engineered Polymers Advanced Ceramics Specialty Metals |

Thread Options

Fragen?