Gaskets ideal for caustic alkali corrosive solutions

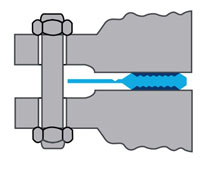

| JG/JP Gasket |

|

Parameters

|

Applications

|

Advantages

|

- Excellent corrosion resistance to caustic soda

- Moderate general corrosion resistance

- Chemistry, specifications & Mechanical Data

- Availability of Nickel 200 gaskets

- Nickel 200 datasheet

Overview of Nickel 200 Gaskets

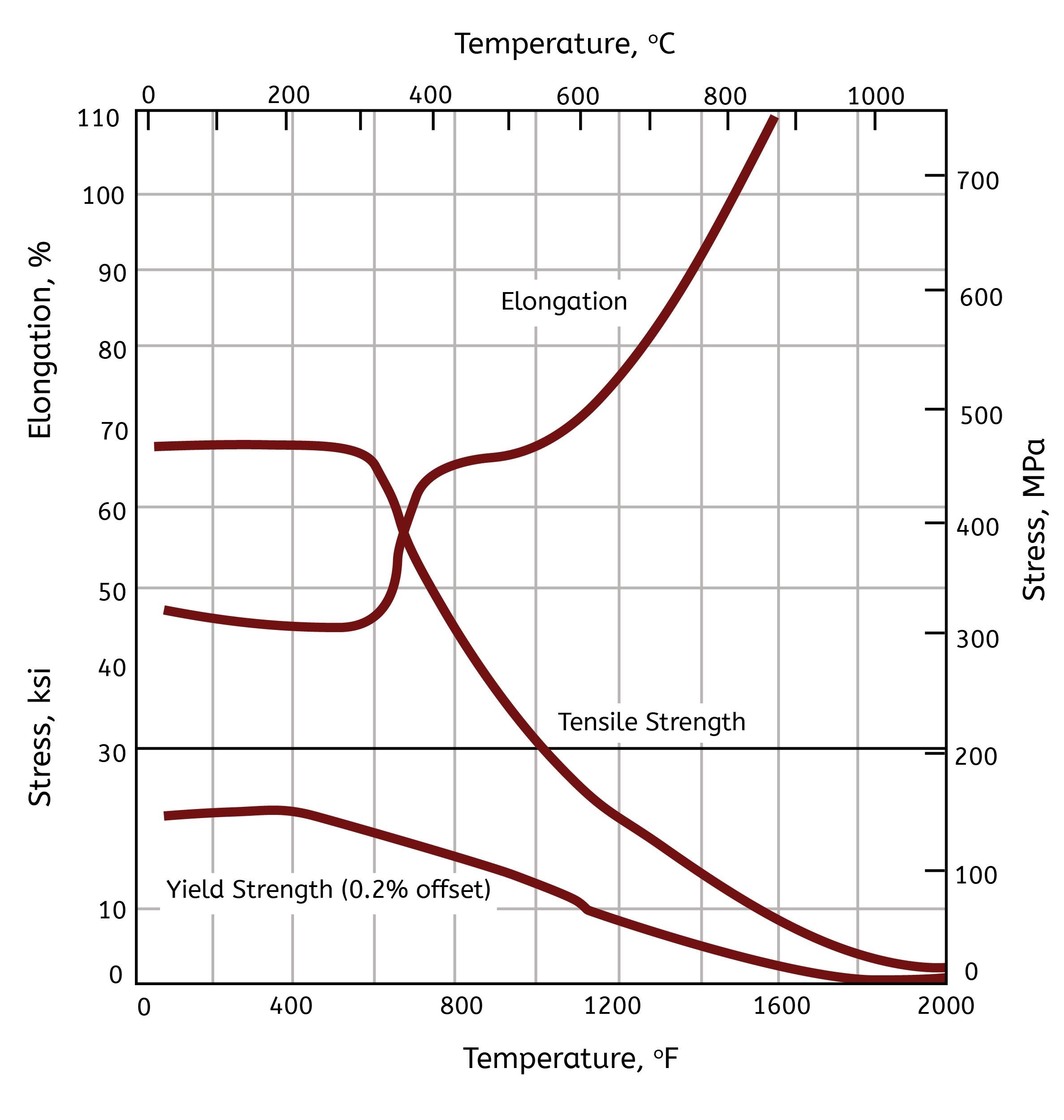

Nickel 200 gaskets are made from commercially pure nickel and are best known for their excellent performance in caustic alkali solutions such as caustic soda (NaOH). Nickel 200 also exhibits good performance in acids, especially HF (Hydrofluoric Acid - anhydrous) and hydroxides – but can be attacked by common solutions of hydrochloric or sulfuric acids. From a mechanical perspective, Nickel 200 gaskets have good ductility and low hardness, so they are tough, but not particularly strong (60-85 KSI UTS). See Tensile, Yield & Elongation Chart.

Nickel 200 semi-metalic gaskets with a PTFE or graphite soft sealing material are available in the Revoseal JG / JP design which is usable in the most corrosive environments and has a pressure rating of from vacuum to 5800psi / 400bar. WIth a leak rate 15000x less than spiral wound gaskets, you can be sure that hazardous fumes and vapors will be conatained creating the safest work environment possible. Furthermore, our Nickel 200 gaskets are customizable and accomodate dissimilar flange faces and large gaps.

Corrosion

Nickel 200 gaskets are resistant to corrosive environments, most notably reducing chemicals. They offer outstanding protection to caustic alkaline solutions. However, Nickel 200 gaskets will be severely attacked in oxidizing salt solutions.

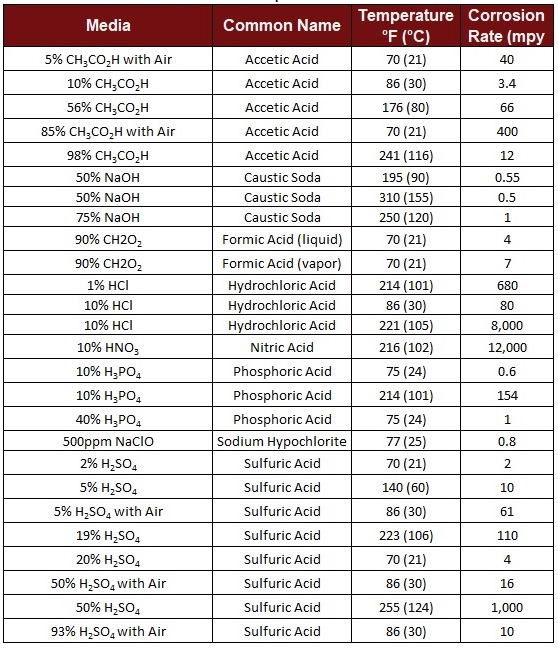

Chemical Resistance

• Sodium Hydroxide (NaOH): Excellent resistance to all concentrations of caustic soda.

• Alkalis: Excellent resistance except for ammonium hydroxide.

• Sulfuric acid: Moderate resistance to nonaerated sulfuric acid solutions near room temperature.

• Hydrochloric: Limited resistance in specific environments only.

• Hydrofluoric: Good resistance to anhydrous hydrofluoric acid even at high temperatures. Nickel 200 it has limited resistance to aqueous HF solutions.

• Important: Oxidizing acid chlorides such as ferric, cupric and mercuric are very corrosive to Nickel 200 gaskets.

General

• 60-85 KSI UTS

• 15-45 KSI Yield

• Typically used in application temperatures less than 600⁰F / 315⁰C

Applications

• Most often used in chemical and electronic processing, especially applications that deal with caustic soda.

• High electrical and thermal conductivity, as well as magnetostrictive properties make Nickel 200 gaskets useful in electrics and sonic devices.

• Nickel 200 gaskets are used in salt production and applications that use sodium hydroxide and fluorine.

Nickel 200 Gasket Availability

Custom Availability

Nickel 200 gaskets can be made to order in both standard and custom designs with normal lead time of approximately 4 weeks. Be sure to contact us for specific lead times and any expediting needs.

- Max dimension: 144in / 4000mm

- Custom to print available

- NACE MR0175, ASTM, ASME, DFAR and Domestic available

Expediting Options

We understand you may have critical needs that require expedited lead times. Please let us know when requesting a quote so we can do our best to help.

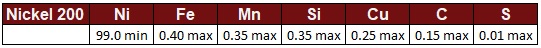

Nickel 200 Chemistry and Specifications

NICKEL 200 SPECIFICATIONS: UNS N02200, EN 2.4060, EN 2.40666

Nickel 200 Aqueous Corrosion Data