When nickel, titanium or zirconium alloys are not enough...

| JG/JP Gasket |

|

Parameters

|

Applications

|

Advantages

|

- Immune to numerous acids and chemicals (corrosion tables)

- Better corrosion resistance than nickel alloys, titanium or zirconium

- High strength and stiffness in vacuum and inert gas up to 2000°C (3600°F)

- Can become brittle when used in oxygen above 300°C

- High purity and biocompatibilty

- Physical Properties

- Tantalum's Chemistry Grades & Specs

- Gasket availability and lead time

- Datasheet for tantalum

Overview of Tantalum Gaskets

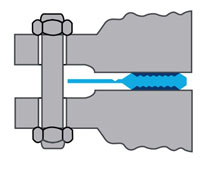

Tantalum gaskets are best known for its unmatched corrosion resistance and chemical inertness. Tantalum has a similar corrosion resistance to that of glass, but all of the typical mechanical and electrical properties of a metal. Tantalum semi-metalic gaskets with a PTFE or graphite soft sealing material are available in the Revoseal JG / JP design which is usable in the most corrosive environments and has a pressure rating of from vacuum to 5800psi / 400bar. WIth a leak rate 15000x less than spiral wound gaskets, you can be sure that hazardous fumes and vapors will be conatained creating the safest work environment possible. Furthermore, our Tantalum gaskets are customizable and accomodate dissimilar flange faces and large gaps.

Tantalum gaskets are also extremely stable at high temperatures, since tantalum has a melting point around 3000°C. High temperature applications require vaccum or inert gas since tantalum may embrittle when used in oxygen rich environments above 250°C. Tantalum gaskets are also one of the most bio-compatible metals available and is also radio-opaque due to its high density (16.68 g/cm3).

Lead time & Availability for Tantalum Gaskets

Custom Availability

Tantalum gaskets can be made to order in both standard and custom designs with normal lead time of approximately 4 weeks. Be sure to contact us for specific lead times and any expediting needs.

- Max dimension: 144in / 4000mm

- Custom to print available

- NACE MR0175, ASTM, ASME, DFAR and Domestic available

Expediting Options

Lead Time is important? You have down equipment? No problem. Just let us know what you need and we will do our very best to accommodate.

Tantalum Grades, Chemistry & Specifications

Tantalum (Commercially Pure)

Commercially pure tantalum metal 99.95% pure tantalum as a minimum and has the best corrosion resistant properties of any metal when it come to most acids. While its corrosion resistance is exceptional, it is relatively soft and mechanically similar in strength to copper.

Specifications: UNS R05200

Tantalum 2.5% Tungsten (Ta-2.5W)

This grade of tantalum alloyed with 2.5% tungsten provided better overall strength while maintaining its exception corrosion resistant properties. For tantalum fasteners & flanges applications this is usually preferred.

Specifications: UNS R05252

Physical Properties

- Density 16.6 g/cc

- Melting Point 3290 K, 2996°C, 5462°F

- Boiling Point 5731 K, 6100°C, 9856°F

- Coefficient of Thermal Expansion (20°C) 6.5 x 10(-6) / °C

- Electrical Resistivity (20°C) 13.5 microhms-cm

- Electrical Conductivity 13% IACS

- Specific Heat .036 cal/g/°C

- Thermal Conductivity .13 cal/cm(2)/cm°C/sec

Tantalum Tensile Data

Tantalum Iso-Corrosion Curves

Tantalum Corrosion Resistance Table

TANTALUM SHOWS A NIL CORROSION RATE TO THE FOLLOWING MEDIAFor all temperatures up to at least 302°F (150°C) unless otherwise indicated | |||

Acetic acid | Chlorine, dry, <250°C (480°F) | Maleic acid | Potassium sulfate |

TANTALUM SHOWS LIMITED CORROSION RESISTANCE TO THE FOLLOWING MEDIA | |||

Air,>300°C (570°F) | Hydrogen, >300°C (570°F)Hydrogen fluoride | Potassium hydroxide, conc. | Sodium hydroxide, conc. |