Exceptional purity and chemical resistance with moderate strength

- High Purity and low extractables

- Chemically resistant to most common solvents including acids, salts, oils and steam

- Mechanical strength and toughness to 150°C (300°F)

- Resistance to ultraviolet, nuclear radiation, and standard sterilization methods

- Resistance to weathering and fungi

- Material datasheet for PVDF

- PVDF flat head screw features and benefits

PVDF / Kynar® flat head screws are made from a tough engineered fluoro-thermoplastic that offers a unique balance of excellent chemical resistance and good strength properties.

PVDF flat head screws have the characteristic stability of fluoropolymers when exposed to harsh chemical and ultraviolet environments but are much stronger mechanically than PTFE or PFA polymers. PVDF screws also excel in high purity and low-permeability applications such as pharmaceutical and semi-conductor processing.

PVDF flat head screws are available in most metric and standard sizes. See our online store (top right) for common sizes or contact us for your specific requirements.

Screw Types: Flat Head Screws, Hex Cap Screws, Pan Head Screws, Set Screws, Socket Head Cap Screws

PVDF Flat Head Screw Features and Benefits

PVDF flat head screws are characterized by having a head with a top flat surface (which can feature either a slotted, phillips or allen driver) and bottom that is cone shaped or countersunk. With this design, the head of the screw can align flush or below the surrounding surface having obvious benefits.

PVDF Slotted vs. Phillips Driver

| Slotted Head Advantages | Phillips Head Advantages |

|

|

Countersink Angle

For most flat head screw designs the angle of countersink is usually 82° for UNC and UNF applications however other angles ranging from 60° -120° could be specified.

| Thread Type | Normal Flat Head Countersink Angle |

UNC / UNF | 82° |

| Aerospace | 100° |

| ISO Metric / Imperial | 90° |

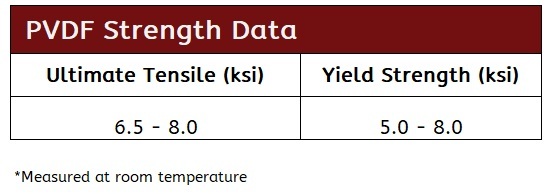

PVDF Mechanical & Physical Properties

|  |