A mid-ranged corrosion resistant 6Mo alloy with good strength

- 50% stronger than stainless steel

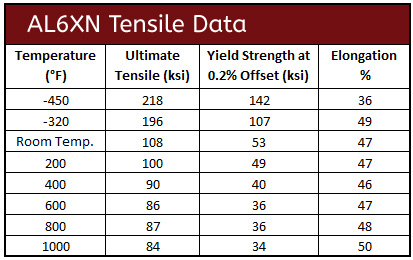

- Usable temperature limit of 1000°F

- AL6XN chemistry & specifications

- Weld neck flange features and benefits

- AL6XN Datasheet

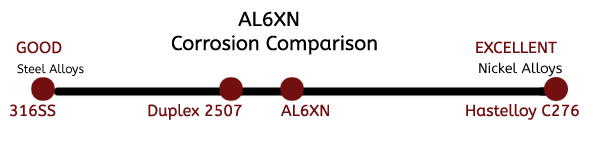

Originally developed to combat sea water corrosion, AL6XN has expanded its role as being good mid-range corrosion resistant alloy. AL6XN weld neck flanges are a low carbon, high purity, nitrogen-bearing "super-austenitic" stainless alloy. Also considered a 6Moly alloy, AL6XN flanges are similar in chemistry and capabilities to Alloy 926 and SMO 254. With a higher nickel and molybdenum content than Duplex 2205 and Super Duplex 2507, it delivers better corrosion resistance while giving a more cost effective alternative to nickel super alloys like Inconel or Hastelloy in moderately corrosive conditions.

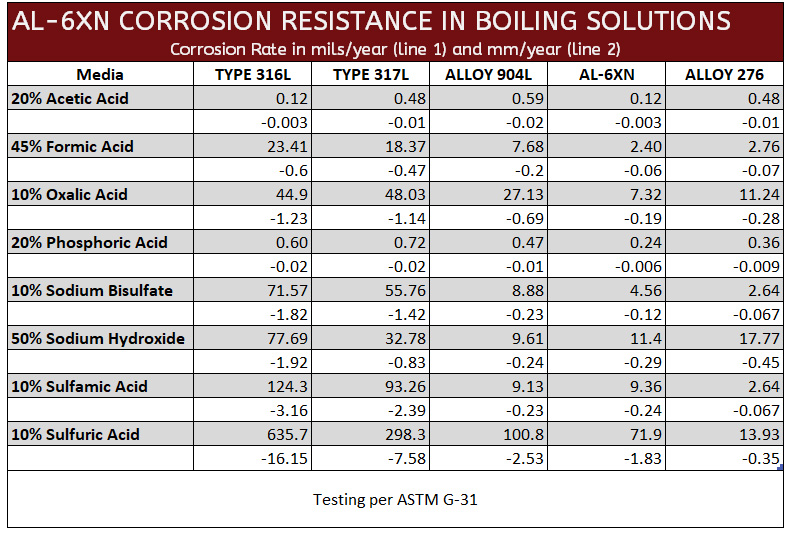

Corrosion Resistance

• Moderate general corrosion resistance

• Excellent chloride / salt water protection

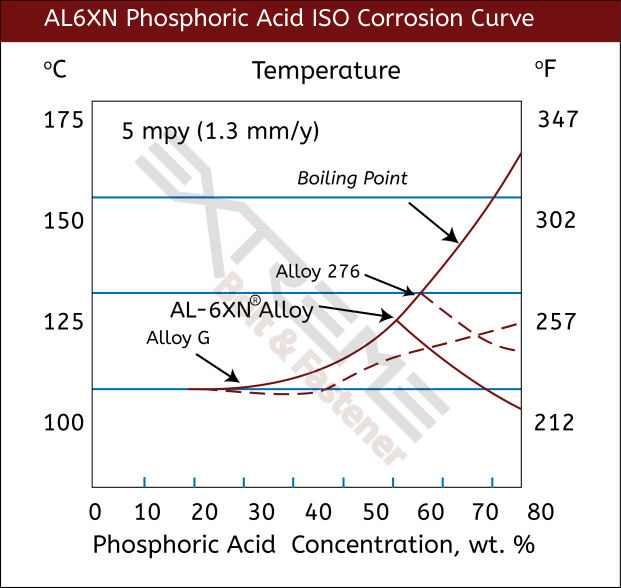

• Good performance in phosphoric acid

• Moderate resistance to nitric acid

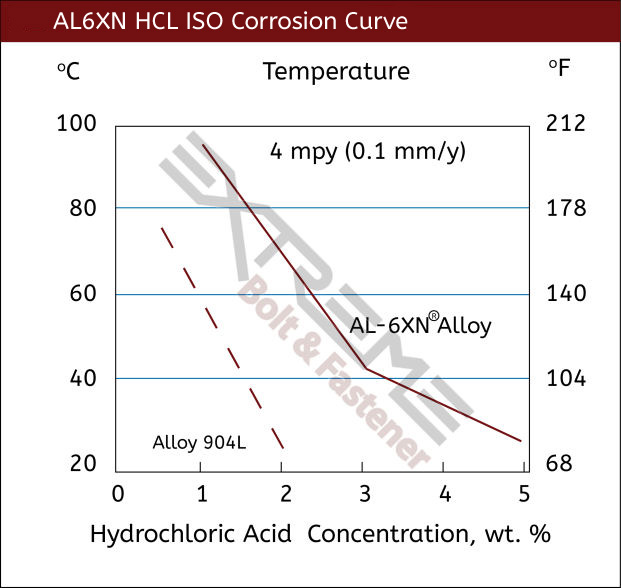

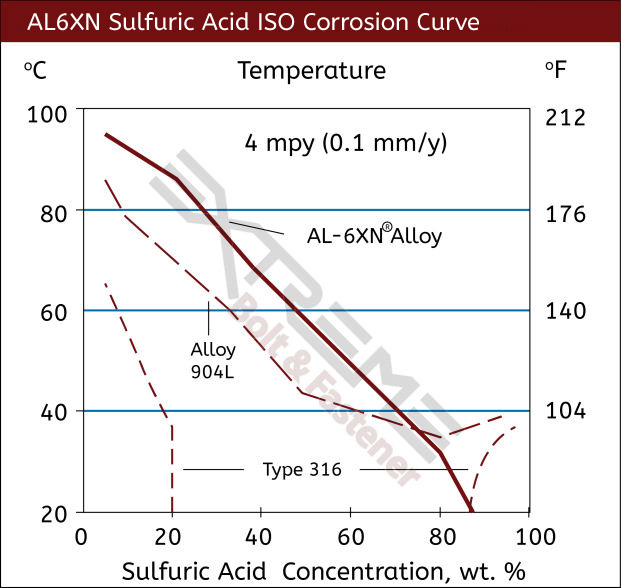

Chemical Resistance

In chemical processes which utilize chlorides, such as paper mills and waste water, stress corrosion cracking (SCC) is a common culprit for 316L stainless failures. Duplex alloys will outlast environments that will cause SCC in 316 stainless, but for more severe low PH environments, weld neck flanges made from higher nickel content alloys like AL6XN will generally work better. For the most extreme situations, alloys with >45% nickel content like Hastelloy are often considered.

Outstanding Resistance to Salt Water

Seawater is where AL6XN weld neck flanges outperform so many alloys providing protection to stress corrosion cracking, pitting and crevice corrosion in a broad range of marine applications. AL6XN weld neck flanges contain a minimum of 6% molybdenum content and it is this addition of molybdenum that provides the greatest protection against pitting and crevice corrosion.

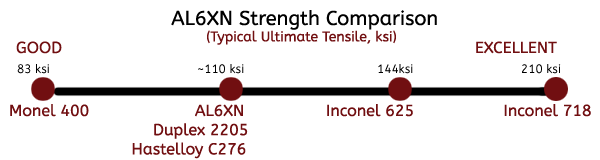

Mechanical Properties

Electrical Resistivity: 535 Ohm-circ mil/ft

Ultimate Tensile Strength: 108 ksi

0.2% Yield Strength: 53 ksi

Density: 0.291 lb/in 3

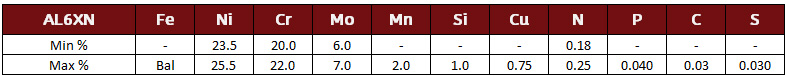

Chemistry

• High molybdenum content provides enhanced corrosion protection in chloride environments.

• Carbon helps to prevent sensitization during welding

• Chromium enhances pitting and crevice corrosion resistance

• The interstitial strengthening effect of nitrogen gives AL6XN weld neck flanges good high strength properties

AL6XN Applications

• Desalination plants depend on AL6XN weld neck flanges for the salt water corrosion protection

• Pulp bleaching equipment and piping

• The power industry uses AL6XN weld neck flanges where salt water and chlorides are present such as steam surface condensers, supercritical, high pressure, feed water heaters, steam surface condensers, flue-gas desulfurization equipment and in nuclear power water piping

• Offshore

• Chemical Processing - processing tanks, vessels and pipes as well as plate and frame heat exchangers.

Resources: AL6XN Torque Specs, Flange Dimensions, Flange Bolting Chart

Flange Types Available: Blind Flanges, Lap Joint Flanges, Slip On Flanges, Socket Weld Flanges, Threaded Flanges, Weld Neck Flanges

AL6XN Chemical Composition & Specifications

AL6XN Specifications: UNS N08367, ASTM A 240, ASTM B 688, ASME SA-240, ASME SB-688, ASTM B690, ASTM B691, ASTM A240, ASTM B688, ASME SA-240, ASME SB-688

AL6XN Mechanical Data

Corrosion Curves for AL6XN

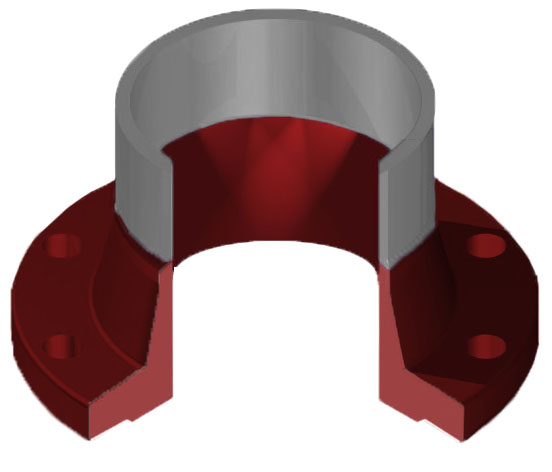

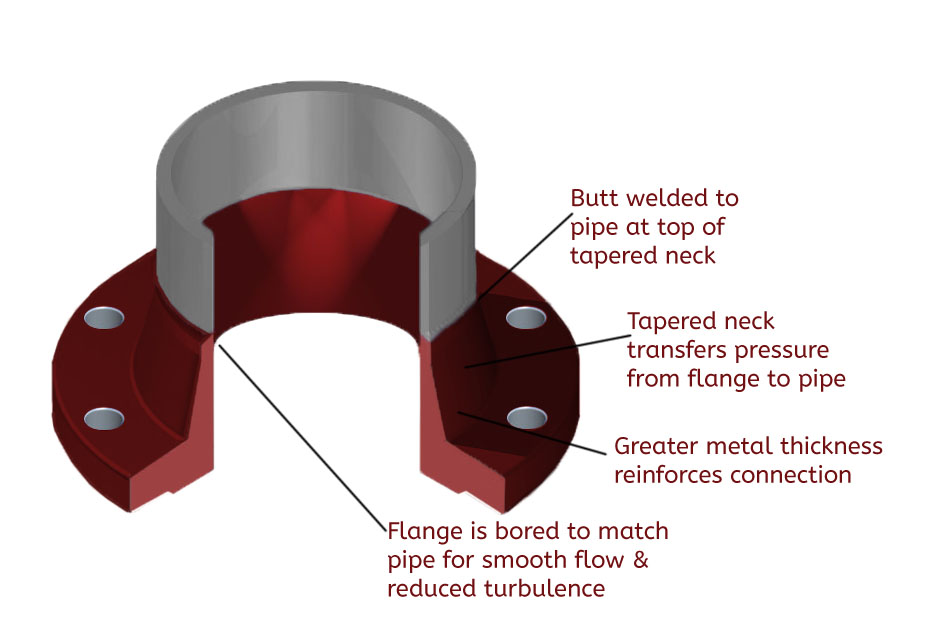

AL6XN Weld Neck Flange Features & Benefits

AL6XN weld neck flanges are best for hazardous, high pressure applications. Weld neck flanges are easily identified by their long tapered neck. The inside of the flange is bored to match the inside diameter of the pipe in order to ensure there is no restriction in flow and also to prevent turbulence at the joint. The tapered neck provides thicker metal at the flange joint, while the neck narrows down gradually to meet the pipe where it is butt welded to the pipe. This design helps to transfer stress from the flange to the pipe, as well as diminish stress concentration at the base of the flange connection.

AL6XN weld neck flanges are ideal for critical applications involving high pressure, sub-zero and elevated temperatures, as well as in conditions where fluctuations cause pipe expansion/contraction.

Key Feature: Ideal for high presure applications.

Weld Neck Flange Advantages

- Ability to withstand high pressure – since pipe is welded to the neck of the flange, stress is transferred to the pipe.

- The beveled end that, when connected to a pipe, creates a trough for a strong weld.

- Most versatile flange in the ASME stable of flanges.

Weld Neck Flange Disadvantages

- More advanced welding skill is needed for installation. The inside weld must be smooth to reduce friction and the outside weld must meet code criteria.

Uses

- Severe conditions that include high-pressure, high-cyclic and hazardous fluid applications.

- Fitting-to-fitting fabrication where the flange is welded directly to a fitting, such as an elbow, without the need for a short piece of pipe, as would be required with a slip-on flange.