Good Mid-Range Corrosion Resistant Alloy

Good Mid-Range Corrosion Resistant Alloy

- Mid-range corrosion resistant alloy

- Decent mechanical strength to 1000°F

- Alloy 20 chemistry and specifications

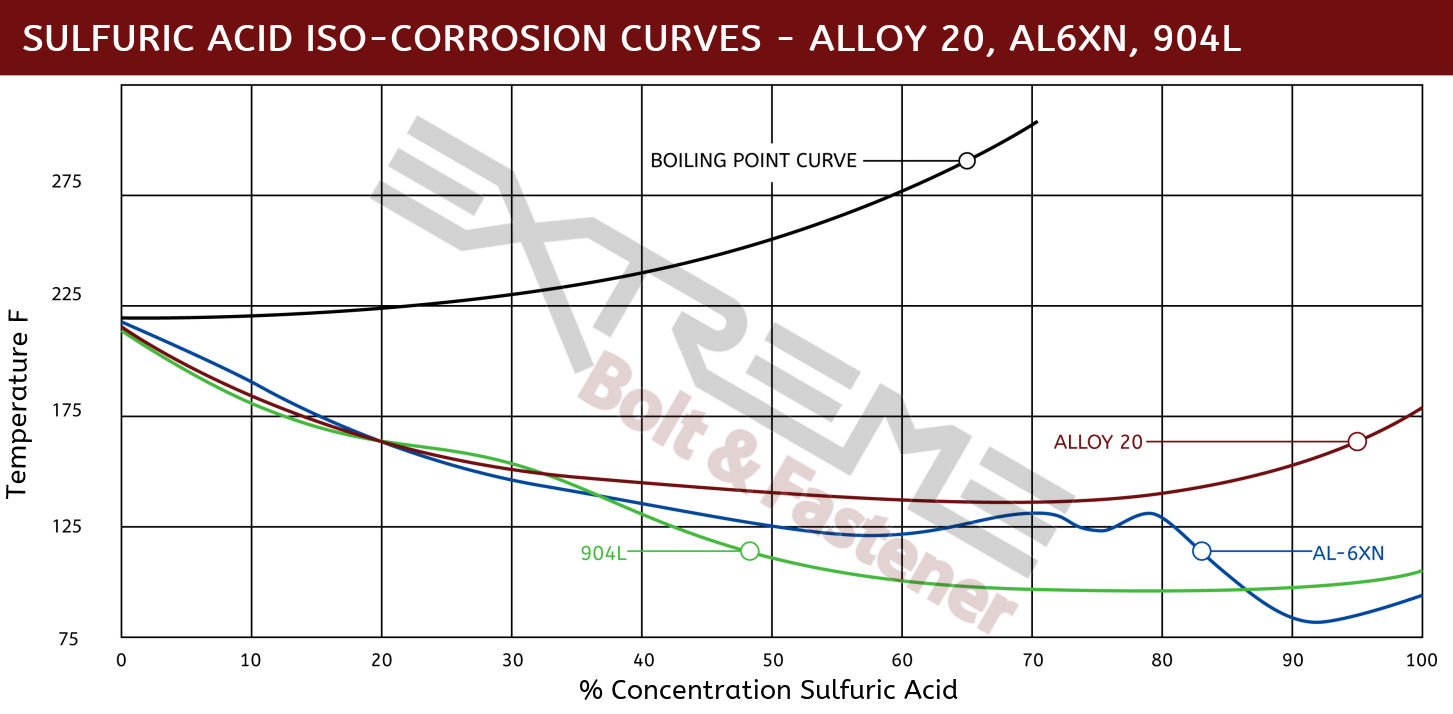

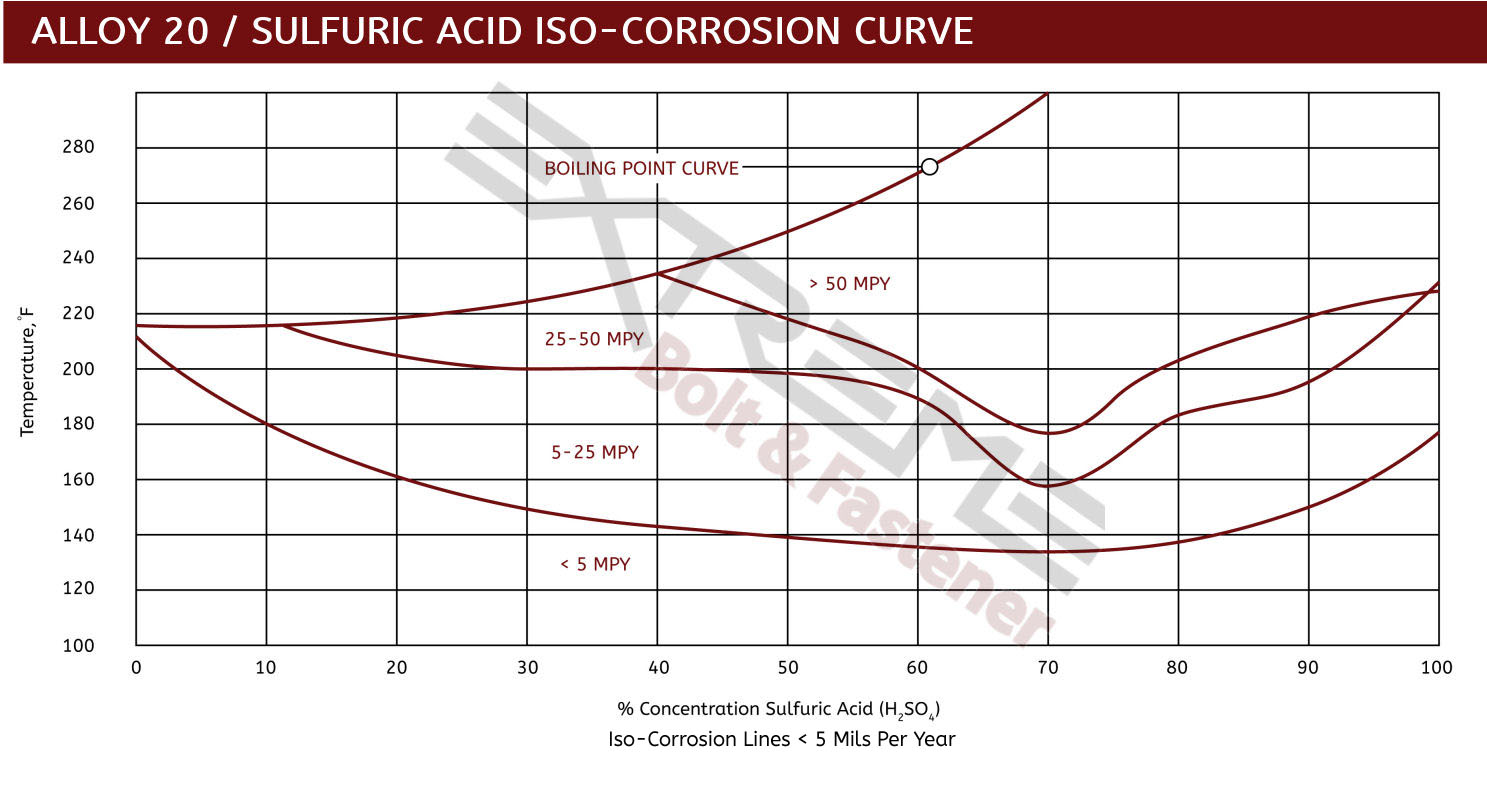

- Alloy 20 sulfric acid performance

- Hex head cap screw features and benefits

- Alloy 20 Datasheet

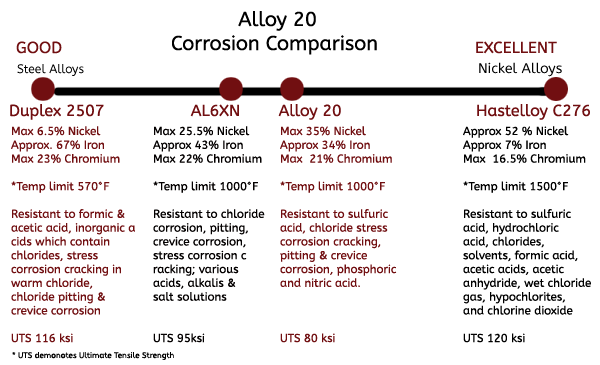

Also known as Carpenter 20 and 20CB-3, Alloy 20 hex head cap screws offer users a combination of nickel, chromium, molybdenum, and copper which provides good general corrosion resistance. Alloy 20 hex head cap screws are best suited for mid-range corrosion use – better than steel alloys but not at the level of high performance nickel based alloys like Hastelloy C276. Alloy 20 is a nickel alloy that was specifically designed to withstand the harsh environment of hot sulfuric acid but also performs well in a variety of other acids. Alloy 20 hex head cap screws are an ideal choice when you don’t need the corrosion resistance power and price-tag of high performance nickel alloys like Hastelloy C276; but you need something that will give you more protection than 316 stainless steel or even a Super Duplex 2507 stainless steel.

Corrosion Resistance

Alloy 20 hex head cap screws provide good performance in hot sulfuric acid, specifically they offer good resistance to stress-corrosion cracking in boiling sulfuric acid at specific range of 20% to 40% concentration, as well as general sulfuric acid resistance. Alloy 20 offers solid acid protection and will perform better than Duplex or even Monel, but for high temperature and high concentration acids, you may need to look to Inconel or Hastelloy fasteners. In addition, Alloy 20 hex head cap screws also show useful resistance to phosphoric acid and nitric acid.

Key Corrosion Resistant Features:

- Good sulfuric acid protection at 20% - 40%

- Decent stress corrosion cracking, pitting and crevice corrosion resistance in chloride

- Resonable general corrosion protection

- Good intergranular corrosion resistance in the as-welded condition

Mechanical Properties

• Ultimate tensile strength: 80 ksi

• Yield strength: 35 ksi

• Density: 0.292 lb/in.3

• Electrical Resistivity (RT) 651 ohm-cir mil/ft

• Elongation: 30%

Temperature

In addition to their corrosion resistance, Alloy 20 hex head cap screws also perform well at moderately high temperatures, with the ability to maintain their mechanical strength up to 1000°F.

Welding

Alloy 20 hex head cap screws are stabilized with Columbium to minimize carbide precipitation during welding. In addition it offers intergranular corrosion resistance in the as-welded condition.

Applications

• Power plants rely on alloy 20 hex head cap screws for flue-gas desulfurization

• Alloy 20 hex head cap screws are used to connect heat exchangers, mixing tanks, metal cleaning equipment, pickling tanks and racks, and piping in mid-range corrosive chemcial processing environments.

• Alloy 20 hex head cap screws help solve corrosion issues in food and dye production.

• Manufacturers of plastics and synthetic rubber also utilize alloy 20 fasteners.

Resources: Alloy 20 Torque Specs, Flange Dimensions, Flange Bolting Chart

Alloy 20 Screw Types: 12 Point Screws, Button Head Cap Screws, Flat Head Screws, Hex Head Cap Screws, Pan Head Screws, Set Screws, Socket Head Cap Screws, Tamper Resistant Security Screws, Torx Screws

Alloy 20 Hex Head Cap Screw Features and Benefits

It is important to differentiate between a Alloy 20 hex head cap screw and hex head bolt. Often people assume they are the same, but they are actually very different fasteners in terms of how they are manufactured, as well as from an application perspective. Regardless of your choice, Alloy 20 hex heads offer strong, stable joints because of their large head service.

The Hex Comparison

| Hex Head Cap Screw | Hex Head Bolts |

|

|

Alloy 20 Hex Head Cap Screw Advantages

The most important feature of a Alloy 20 hex head cap screws is that it has a larger bearing surface area which provide better clamping pressure than other type of fastener such as a socket head cap screw. Additionally, since debris build up is less of an issue with this style of fastener verses a socket head cap screw, they are ideal of dirty applications where particles could clog up a socket. Though Alloy 20 socket heads are typically used for tight access applications, hex heads can be a better choice when there is only side clearance available for tightening.

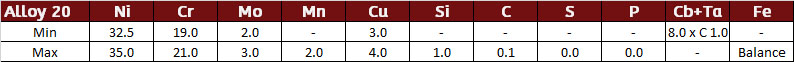

Alloy 20 Chemistry & Specifications

Alloy 20 Specifications: UNS N08020, ASME SA240, , ASME SB366, ASME SB462, ASME SB463, ASME SB464, ASME SB473, ASME SB729, ASTM A240, ASTM B366, ASTM B463, ASTM B464, ASTM B473, ASTM B729, ASTM BB462, ANSI/ASTM A555-79, EN 2.4660, , Werkstoff 2.4660, CN7M, DIN 2.4660

Alloy 20 Sulfuric Acid Performance

Alloy 20 Sulfuric Acid Comparison