- Monel 400 grades and chemistry

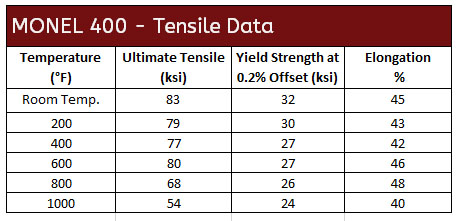

- Mechanical properties, tensile data and pressure ratings

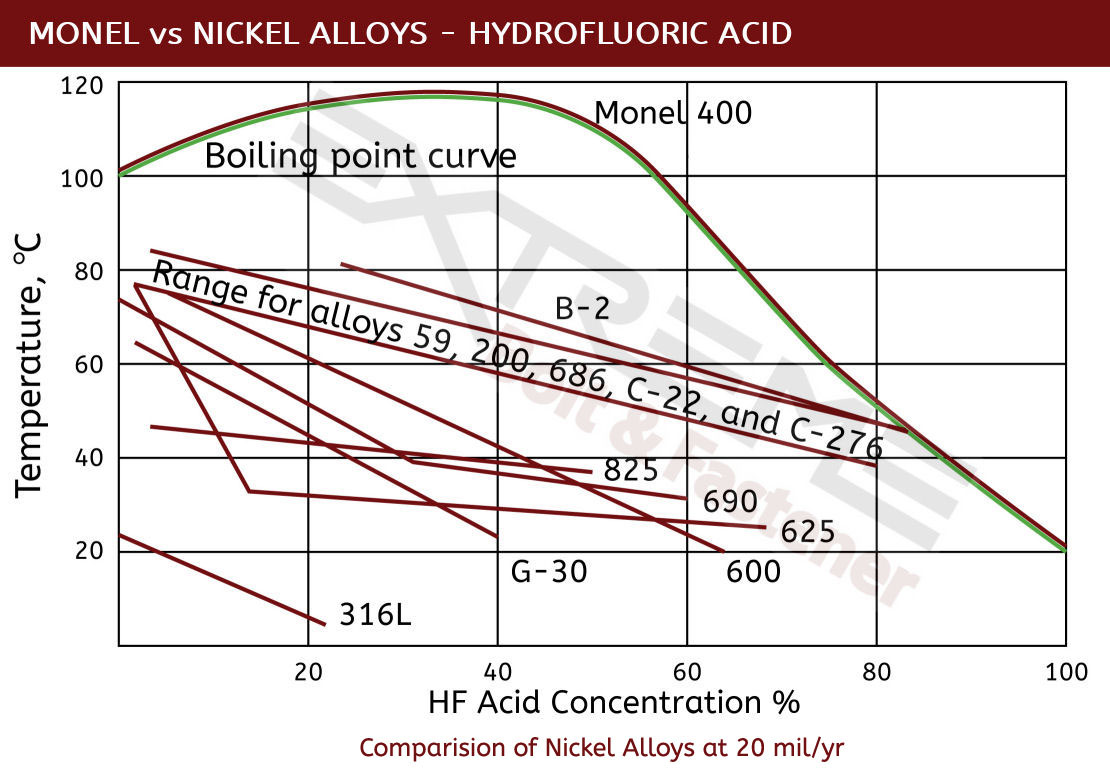

- Monel 400 corrosion data

- Datasheet for Monel 400

A nickel-copper alloy, Monel 400 fasteners and flanges are a solid solution nickel alloy that can only be hardened by cold working. Best known for its corrosion resistance to reducing media and seawater, Monel 400 is also tougher in oxidizing environments than copper alloys. Also known as alloy 400, Monel 400 fasteners and flanges are also utilized in high temperature, caustic and salt solution applications.

High Temperature and Cryogenic Properties

Used for high temperature applications up to 1000°F in oxidizing atmospheres, Monel 400 fasteners can also be used at higher temperatures if in a reducing environment. Though commonly used at high temperatures, Monel 400 fasteners and flanges also retain their mechanical properties at subzero temperatures. Increased hardness at freezing temperatures has been shown to only slightly impair the ductility or impact resistance of Monel 400 fasteners. Even when cooled to cryogenic temperatures, Monel 400 does not undergo a ductile-to-brittle transition which can cause fractures. This is especially unique compared to most ferrous materials which are often stronger, yet very brittle at extreme low temperatures.

Renowned Seawater Resistance

Perhaps the best attribute of Monel 400 fasteners and flanges is their ability to defy seawater corrosion. Uniquely, they offer resistance to rapidly moving seawater, which can erode other materials, though stagnant salt water situations can sometimes result in crevice and pitting corrosion. In addition, Monel 400 fasteners and flanges prevent stress corrosion cracking and pitting in most fresh and industrial waters.

General Corrosion Protection

Though it is best known for its resistance to sea water, Monel 400 fasteners and flanges also show good resistance reducing media. It also resists oxidizing media better than many alloys with higher copper content. When it comes to acids, Monel 400 fasteners offer very good protection from hydrofluoric acid in all concentrations up to the boiling point, as well as decent protection to sulfuric and hydrochloric acids under reducing conditions.

Monel 400 Fasteners & Flanges in Action: Extreme Applications

- Saltwater resistance makes it critical to maritime components.

- Chemical processing industries often choose Monel 400 fasteners for equipment, process vessels, boilers and heaters.

- Offshore oil and gas drilling utilize Monel 400 fasteners and flanges for seawater corrosion protection.

Resources: Monel Torque Spec, Flange Dimensions, Flange Bolting Chart

Monel Fastener Types: Bolts, Nuts, Screws, Threaded Rods, Washers

Flange Types Available: Blind Flanges, Lap Joint Flanges, Slip On Flanges, Socket Weld Flanges, Threaded Flanges, Weld Neck Flanges

Monel 400 Chemistry and Specifications

Monel 400 (alloy 400), UNS N04400 (QQ-N-281), is a nickel-copper alloy with high strength and excellent corrosion resistance in a range of media including sea water, hydrofluoric acid, sulfuric acid, and alkalies. Monel 400 is commonly in marine engineering, chemical and hydrocarbon processing applications.

Monel 400 Specifications: BS3075NA13 (Wire), BS3076NA13 (Bar), ASTM B 164 (Rod, Bar, and Wire), ASTM B 564 (Forgings), ASME SB 164 (Rod, Bar, and Wire), ASME SB 564 (Forgings), AECMA PrEN 2305 (Wire for Rivets), SAE AMS 4675 (Bars and Forgings), SAE AMS 4730 (Wire), SAE AMS 4731 (Wire and Ribbon), DIN 17752 (Rod and Bar), DIN 17753 (Wire), DIN 17754 (Forgings), VdTÜV 263 (Sheet, Plate, Bar, and Tubing), QQ-N-281 (Plate, Sheet, Strip, Bar, Rod, Wire, and Forgings), Werkstoff 2.4360

Mechanical Properties of Alloy 400

Monel 400 Corrosion Data