When nickel, titanium or zirconium alloys are not enough...

- Immune to numerous acids and chemicals (corrosion tables)

- Better corrosion resistance than nickel alloys, titanium or zirconium

- High strength and stiffness in vacuum and inert gas up to 2000°C (3600°F)

- Can become brittle when used in oxygen above 300°C

- High purity and biocompatibilty

- Tantalum grades, specifications and chemistry

- Datasheet for tantalum

- Lap joint flange features and benefits

Tantalum lap joint flanges are best known for its unmatched corrosion resistance and chemical inertness. Tantalum lap joint flanges have a similar corrosion resistance to that of glass, but all of the typical mechanical and electrical properties of a metal.

Tantalum lap joint flanges are also extremely stable at high temperatures, since tantalum has a melting point around 3000°C. High temperature applications require vaccum or inert gas since tantalum may embrittle when used in oxygen rich environments above 250°C. Tantalum lap joint flanges are also one of the most bio-compatible metals available and is also radio-opaque due to its high density (16.68 g/cm3).

All tantalum lap joint flanges are available in the form of a tantalum loose linings or with the Ultra-Metal tantalum diffusion surface on select flange styles. Due to the cost and limited mechanical properties of tantalum, solid tantalum lap joint flanges are rarely used.

Contact our engineers to learn if tantalum lap joint flanges are right for your application.

Resources: Tantalum Torque Spec, Flange Dimensions, Flange Bolting Chart

Flange Types Available: Blind Flanges, Lap Joint Flanges, Slip On Flanges, Socket Weld Flanges, Threaded Flanges, Weld Neck Flanges

Tantalum Grades, Specifications and Chemistry

Tantalum (Commercially Pure)

Commercially pure tantalum metal is 99.95% pure tantalum has some o the best corrosion resistant properties of any metal. While its corrosion resistance is exceptional, it is relatively soft and mechanically similar in strength to copper.

Tantalum Specifications: UNS R05200, ASTM B521, ASTM B708, ASTM B365

Tantalum 2.5% Tungsten (Ta-2.5W)

This grade of tantalum alloyed with 2.5% tungsten provided better overall strength while maintaining its exception corrosion resistant properties. For tantalum fastener applications this is usually preferred.

Tantalum 2.5% Tungsten Specifications: UNS R05200, ASTM B521, ASTM B708, ASTM B365

Physical Properties

- Density 16.6 g/cc

- Melting Point 3290 K, 2996°C, 5462°F

- Boiling Point 5731 K, 6100°C, 9856°F

- Coefficient of Thermal Expansion (20°C) 6.5 x 10(-6) / °C

- Electrical Resistivity (20°C) 13.5 microhms-cm

- Electrical Conductivity 13% IACS

- Specific Heat .036 cal/g/°C

- Thermal Conductivity .13 cal/cm(2)/cm°C/sec

Tantalum Tensile Data

Tantalum Iso-Corrosion Curves

Tantalum Corrosion Resistance Table

TANTALUM SHOWS A NIL CORROSION RATE TO THE FOLLOWING MEDIAFor all temperatures up to at least 302F (150C) unless otherwise indicated | |||

Acetic acid | Chlorine, dry, <250°C (480°F) | Maleic acid | Potassium sulfate |

TANTALUM SHOWS LIMITED CORROSION RESISTANCE TO THE FOLLOWING MEDIA | |||

Air,>300°C (570°F) | Hydrogen, >300°C (570°F)Hydrogen fluoride | Potassium hydroxide, conc. | Sodium hydroxide, conc. |

Tantalum Lap Joint Flange Features & Benefits

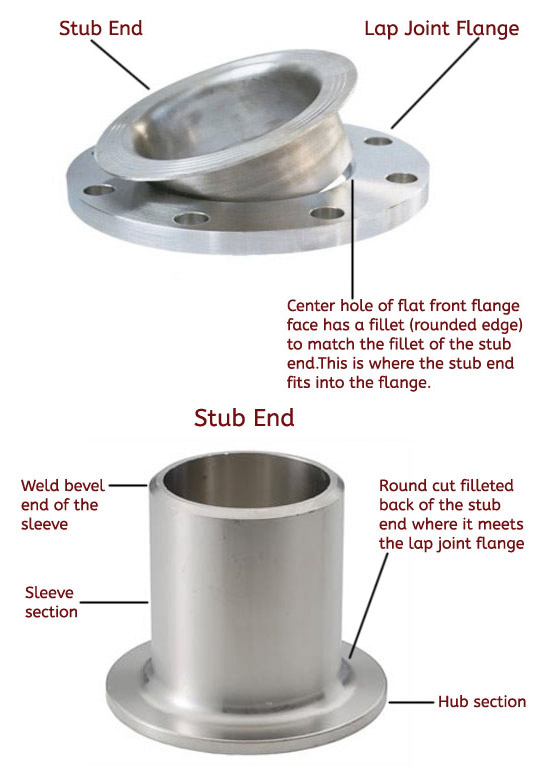

Lap joint flanges are unique in that they are made of two pieces, the flange itself and the stub end.

Flange

- The backside, has a slight shoulder that is square cut at the center or pipe hole

- The front side has a flat face with a filleted (rounded) center hole to match the filleted back face of the stub end. Here the stub end will wrap tightly around the center hole of the flange.

Stub End

- Shaped like a short piece of pipe with a weld bevel on one. This portion of the stub end is also called the sleeve.

- Narrow shoulder on the flange facing end called is the hub. The back face of the hub has a rounded transition (or inside fillet) that joins the hub to the sleeve

Benefits

- Economy

Because a lap joint flange has a two piece configuration, it offers a way to cut cost when piping systems requires - For high cost alloys the only "wetted" part is the stub end. In this situation, it is only required for the stub-end to be made of the higher cost corrosion-resistant material, where the flange itself can be the produced from lower cost steel.

- Ease of Work

By using lap joint flanges, work can be simplified in situations that require frequent and rapid disassemble and assembly during the operation of a plant. The ability to spin that backing flange compensates for misalignment of the bolt holes during assembly.