When nickel, titanium or zirconium alloys are not enough...

- Immune to numerous acids and chemicals (corrosion tables)

- Better corrosion resistance than nickel alloys, titanium or zirconium

- High strength and stiffness in vacuum and inert gas up to 2000°C (3600°F)

- Can become brittle when used in oxygen above 300°C

- High purity and biocompatibilty

- Physical Properties

- Tantalum grades, specifications and chemistry

- Datasheet for tantalum

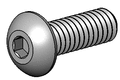

- Tantalum button head cap screw features and benefits

Tantalum button head cap screws are best known for its unmatched corrosion resistance and chemical inertness. Tantalum screws have a similar corrosion resistance to that of glass, but all of the typical mechanical and electrical properties of a metal.

Tantalum screws are also extremely stable at high temperatures, since tantalum has a melting point around 3000°C. High temperature applications require vaccum or inert gas since tantalum may embrittle when used in oxygen rich environments above 250°C. Tantalum button head cap screws are also one of the most bio-compatible metals available and is also radio-opaque due to its high density (16.68 g/cm3).

All tantalum button head cap screws are available in commercially pure tantalum and tantalum 2.5% tungsten (Ta-2.5%W).

Contact us to see if your required tantalum screws are in stock and how our engineers may help you with your tantalum fastener application.

Resources: Tantalum Torque Spec

Screw Types: Button Head Cap Screws, Flat Head Screws, Hex Cap Screws, Pan Head Screws, Set Screws, Socket Head Cap Screws, Tamper Resistant Security Screws,

Tantalum Button Head Cap Screw Features & Benefits

Tantalum button head cap screws combine the similar shape of a pan head with the driver of a socket head. The socket driver is ideal for low clearance applications that require a large area clamping face. Compared to a standard socket head cap screw, tantalum button heads have a lower and wider profile. This can be useful when the clamping material is too thin to counter-bore.

Advantages

- Wide bearing surface for clamping

- Low profile head

Tantalum Grades, Specifications and Chemistry

Tantalum (Commercially Pure)

Commercially pure tantalum metal is 99.95% pure tantalum has some o the best corrosion resistant properties of any metal. While its corrosion resistance is exceptional, it is relatively soft and mechanically similar in strength to copper.

Tantalum Specifications: UNS R05200, ASTM B521, ASTM B708, ASTM B365

Tantalum 2.5% Tungsten (Ta-2.5W)

This grade of tantalum alloyed with 2.5% tungsten provided better overall strength while maintaining its exception corrosion resistant properties. For tantalum fastener applications this is usually preferred.

Tantalum 2.5% Tungsten Specifications: UNS R05200, ASTM B521, ASTM B708, ASTM B365

Physical Properties

- Density 16.6 g/cc

- Melting Point 3290 K, 2996°C, 5462°F

- Boiling Point 5731 K, 6100°C, 9856°F

- Coefficient of Thermal Expansion (20°C) 6.5 x 10(-6) / °C

- Electrical Resistivity (20°C) 13.5 microhms-cm

- Electrical Conductivity 13% IACS

- Specific Heat .036 cal/g/°C

- Thermal Conductivity .13 cal/cm(2)/cm°C/sec

Tantalum Tensile Data

Tantalum Iso-Corrosion Curves

Tantalum Corrosion Resistance Table

TANTALUM SHOWS A NIL CORROSION RATE TO THE FOLLOWING MEDIAFor all temperatures up to at least 302F (150C) unless otherwise indicated | |||

Acetic acid | Chlorine, dry, <250°C (480°F) | Maleic acid | Potassium sulfate |

TANTALUM SHOWS LIMITED CORROSION RESISTANCE TO THE FOLLOWING MEDIA | |||

Air,>300°C (570°F) | Hydrogen, >300°C (570°F)Hydrogen fluoride | Potassium hydroxide, conc. | Sodium hydroxide, conc. |