Ultra-high density & high temperature / strength stability

- High strength at extreme high temperatures (vacuum)

- Radiopaque to x-rays and other radiation

- Very high density of 19.3 gm/cc

- Excellent corrosion resistance

- Mechanical properties of tungsten screws

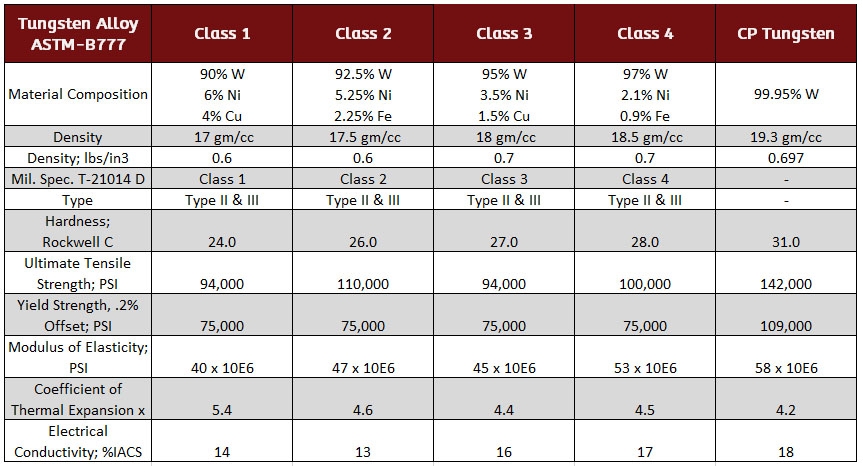

- Tungsten material datasheet

Tungsten screws are an ideal material for high temperature stability. Their extremely high melting point of 3420°C, makes tungsten flat head screws useful for some of the hottest vacuum furnace environments. Another attribute of tungsten is its extreme high density. The high mass of tungsten screws make them radiopaque, allowing them to block radiation and show up well on x-rays – even better than lead. In addition, their high density also makes them ideal for balancing rotating parts. Beyond their high mass and temperature stability, tungsten fasteners are also very corrosion resistant.

Tungsten flat head socket cap screws are usually made from tungsten alloys per ASTM B777, and range from 90% to 97% pure tungsten, alloyed with nickel and copper or nickel and iron. Fasteners can also be made from Commercially Pure (CP) Tungsten.

Applications

- The heat treating / furnace industry uses tungsten flat head screws in high temperature vacuum furnaces due to tungstens great high temperature strength & stability.

- The oil & gas industry uses tungsten screws for radiation shielding properties to protect equipment used in oil and gas detection, as well as down hole logging for density and ability to withstand intense hydrostatic pressure

- Tungsten flat head screws also play a role in the medical community for their low magnetic properties as well as their radiopaque properties.

- The aerospace industry depends on the tungsten screws for their combination of high density and mechanical strength which allows them to reduce the physical size of components, offering greater control of weight distribution for propellers, inertial systems and fluid control systems to name a few.

Resources: Tungsten Torque Specs

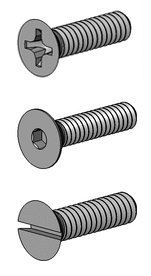

Tungsten Screw Types: Button Head Cap Screws, Flat Head Screws, Hex Head Cap Screws, Pan Head, Set Screws, Socket Head Cap Screws, Tamper Resistant Security Screws

Tungsten Flat Head Screw Features and Benefits

Tungsten flat head screws are characterized by having a head with a top flat surface (which can feature either a slotted, phillips or allen driver) and bottom that is cone shaped or countersunk. With this design, the head of the screw can align flush or below the surrounding surface having obvious benefits.

Tungsten Slotted vs. Phillips Driver

| Slotted Head Advantages | Phillips Head Advantages |

|

|

Countersink Angle

For most flat head screw designs the angle of countersink is usually 82° for UNC and UNF applications however other angles ranging from 60° -120° could be specified.

| Thread Type | Normal Flat Head Countersink Angle |

UNC / UNF | 82° |

| Aerospace | 100° |

| ISO Metric / Imperial | 90° |

Tungsten Chemistry & Specifications

Tungsten Specifications: ASTM B777, Mil Spec T-21014D