An age hardened super alloy with exceptional strength at high temperatures

- Extreme high temperature strength

- Service temperatures up to 1600°F (870°C)

- Very oxidation resistant

- Waspaloy chemistry & specifications

- Datasheet for Waspaloy

- Waspaloy Torx screw features and benefits

Waspaloy Torx screws are known for their superb high strength at elevated temperatures. Waspaloy is a high performance nickel alloy combined with cobalt, chrome and molybdenum to create it’s unique combination of strength and high temperature stability.

Similar to that of Inconel 718 screws, Waspaloy Torx screws exceed the strength and stability of Inconel 718 at elevated temperatures beyond 1400°F. In addition, the oxidation resistance of Waspaloy Torx screws make it an ideal materials for high temperature applications like gas turbines engines, and a variety of other aerospace components.

Resources: Waspaloy Torque Specs

Screw Types: 12 Point Screws, Button Head Cap Screws, Flat Head Screws, Hex Head Cap Screws, Pan Head Screws, Set Screws, Socket Head Cap Screws, Tamper Resistant Security Screws, Torx Screws

Waspaloy Torx Screw Features and Benefits

Waspaloy Torx screws are characterized by a 6-point star-shaped pattern, also called a star drive, spined socket or hexalobular (ISO 10664). Where Phillips heads were designed to cause the driver to cam-out (prevent overtightening), Torx screws were designed resist cam-out. This feature allows Waspaloy Torx screws to provide increased torque as well as better torque transfer between driver and fasteners. This feature also helps to reduce wear on driver bits.

Waspaloy Torx Screw Advantages

- Resistant to cam out (process by which a screwdriver slips out of the head)

- Waspaloy Torx screws are more difficult to strip

- Increased tamper resistance as a star driver isn’t as common

- Driver insert is less susceptible to damage when over torqued than Allen head

Waspaloy Chemistry & Specifications

Waspaloy is a solution annealed and age hardended alloy which provides its high strength properties. There are a few aging varieties however the AMS 5708 is one of the more common.

Waspaloy Specifications: UNS N07001, ASTM B 637, AMS 5708, AMS 5709, EN 2.4654, Werkstoff 2.4654

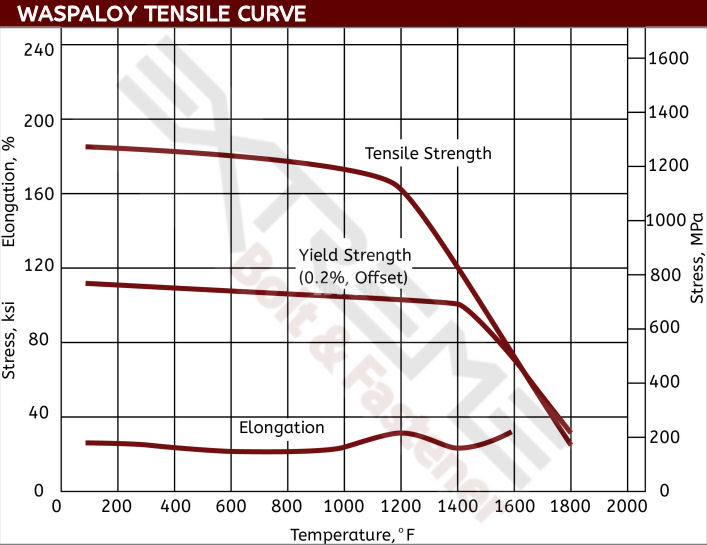

Waspaloy Tensile Curve